Generative artificial intelligence (GenAI) is changing industries worldwide, with manufacturing becoming one of the most promising areas for AI adoption. As global supply chains face major disruptions and manufacturers struggle with widespread labor shortages, generative AI offers practical solutions. From predictive maintenance to personalized mass production, this technology redefines how products are designed, manufactured, and delivered.

In this article, we will explore the top use cases and benefits of generative AI in manufacturing and provide insights into how industry leaders use this technology to gain competitive advantages and improve operational efficiency in today’s dynamic marketplace.

What is generative AI in manufacturing?

Generative AI in manufacturing incorporates advanced AI systems that go beyond traditional data analysis and automation to create new solutions, designs, and working approaches. Unlike conventional AI, which primarily analyzes data or makes predictions, Gen AI actively creates innovative product designs, optimizes production workflows, and enhances decision-making throughout the manufacturing process.

These systems analyze large amounts of historical and present data, identify patterns, and incorporate user feedback to continuously improve their performance. This is Gen AI, acting as a smart digital assistant capable of not only interpreting complex manufacturing data but also providing actionable insights.

When discussing the frameworks of “smart factories” or Industry 4.0, generative AI is a key component of connected, flexible, and highly automated manufacturing systems. It autonomously supports real-time monitoring and adjusts production without human intervention, helping manufacturers achieve greater efficiency and responsiveness in their operations.

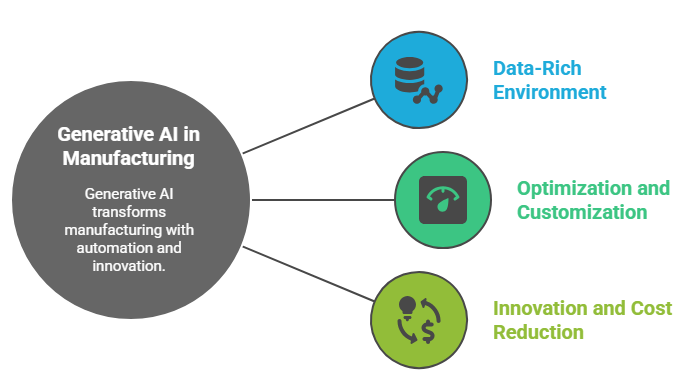

Why generative AI is a game-changer for manufacturing

Manufacturing environments present unique opportunities for generative AI implementation due to their inherent characteristics and operational demands. Here’s what makes manufacturing facilities ideal for AI transformation and what manufacturers can expect from implementing these advanced systems.

Data-rich environment with complex, repetitive tasks

Manufacturing generates massive datasets from sensors, quality control systems, and production logs, providing ideal training material for AI models that can automate repetitive design tasks, documentation processes, and quality assessments across production lines.

Need for optimization, customization, and predictive analysis

Modern manufacturing demands immediate optimization of resources, customized product variants, and predictive insights to prevent failures, requiring AI systems that can generate optimal configurations, predict maintenance needs, and customize products at scale.

Faster innovation cycles and cost reduction through AI

Competitive pressures demand rapid product development and cost minimization, where generative AI accelerates design iterations, reduces prototyping costs, and enables manufacturers to bring innovative products to market faster than traditional methods.

Explore more about Generative AI for Marketing: Application & Best Practices

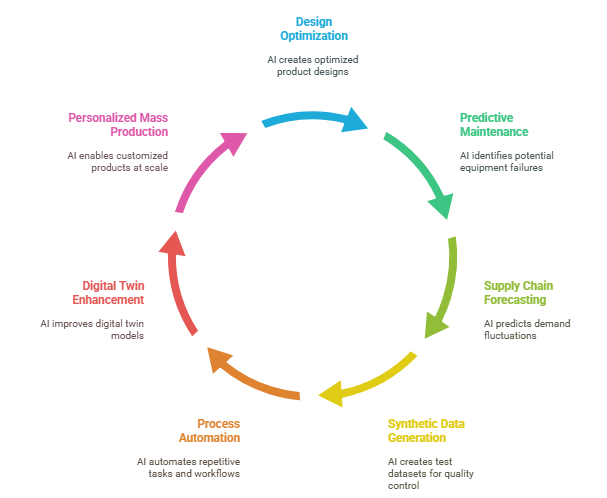

Top use cases of generative AI in manufacturing

Generative AI applications in manufacturing span across design, operations, and supply chain management, offering transformative solutions for industry challenges.

1. Generative design & product innovation

Generative design represents one of the most impactful applications where AI creates optimized product architectures based on specified constraints and performance requirements.

AI suggests optimized product designs based on constraints

Generative algorithms analyze performance requirements, material properties, and manufacturing limitations to propose multiple design alternatives that human engineers might not consider, optimizing for weight, strength, cost, and manufacturability simultaneously.

Speeds up prototyping and reduces material waste

AI-generated designs undergo virtual testing before physical prototyping, reducing the number of physical iterations required and minimizing material waste while accelerating the product development timeline from months to weeks.

Use case: Aerospace or automotive design simulations

Airbus partnered with Autodesk to redesign aircraft cabin partitions using generative AI. The AI system analyzed structural requirements, weight constraints, and safety regulations to create partition designs that were 45% lighter than traditional versions while maintaining the same strength. This weight reduction translates to significant fuel savings over the aircraft’s lifetime.

2. Predictive maintenance with AI-generated patterns

Predictive maintenance uses generative AI to identify subtle patterns in equipment data that indicate potential failures before they occur.

AI identifies early signs of equipment failure

Machine learning models analyze vibration, temperature, sound, and operational data to generate predictive patterns that identify equipment anomalies weeks or months before traditional monitoring systems, enabling proactive maintenance scheduling.

Reduces downtime and extends machine life

Predictive maintenance increases productivity by 25%, reduces breakdowns by 70%, and lowers maintenance costs by 25%, extending equipment lifespan through optimized maintenance intervals and early intervention strategies.

Use case: heavy machinery operations

US Steel implemented Google Cloud’s generative AI at its Minnesota iron ore facility to transform maintenance operations. The system continuously monitors massive mining equipment, including conveyor belts, crushers, and hauling trucks, analyzing vibration patterns, temperature fluctuations, and operational data to predict potential failures weeks in advance, dramatically reducing unplanned downtime.

3. Supply chain & demand forecasting

Generative AI transforms supply chain management by creating sophisticated models that simulate various scenarios and predict demand fluctuations with accuracy.

Generative AI models simulate and predict supply-demand fluctuations

AI systems analyze historical sales data, economic indicators, seasonal patterns, and external factors to generate multiple demand scenarios, enabling manufacturers to prepare for various market conditions and adjust production accordingly.

Learn more about Generative AI for Logistics – Use Cases and Benefits

Inventory optimization, just-in-time manufacturing

Machine learning algorithms generate optimal inventory levels by considering lead times, storage costs, and demand variability, reducing carrying costs while ensuring product availability through intelligent just-in-time manufacturing strategies.

Use Case: Response to global disruptions

The semiconductor shortage that began in 2020 highlighted how AI-powered supply chain systems helped manufacturers navigate unprecedented disruptions. Research shows that companies using data analytics and AI were better positioned to manage supply chain issues during the crisis. These AI systems analyzed real-time data to predict unexpected events like weather conditions, transportation bottlenecks, and labor strikes, helping manufacturers anticipate problems and reroute shipments around disruptions.

4. Synthetic data generation for quality control

Synthetic data generation addresses the problem of insufficient real-world data for training robust quality control systems in manufacturing environments.

Overcome data scarcity with AI-generated test datasets

Generative models create realistic synthetic defect images and sensor data that supplement limited real-world samples, enabling quality control systems to recognize rare defects and edge cases without waiting for actual failures.

Improves the accuracy of defect detection models

AI-generated datasets provide a balanced representation of all defect types, improving model training effectiveness and reducing false positives in automated quality inspection systems by up to 40% compared to models trained solely on limited real data.

Use Case: Quality control in consumer goods manufacturing

Siemens uses synthetic data generation with NVIDIA Omniverse Replicator to accelerate AI model development for quality control from months to days. Their Motion Control Business Unit produces inverters, drive controllers, and motors. It uses AI-enabled computer vision for defect detection across more than 30,000 customers worldwide, enabling automated visual inspection without requiring vision experts.

5. Process automation & workflow optimization

Generative AI streamlines manufacturing processes by automating documentation creation and suggesting synchronized workflow improvements based on operational data analysis.

Automating repetitive tasks such as documentation, SOP creation

AI systems automatically generate standard operating procedures, maintenance manuals, and compliance documentation from production data and best practices, reducing manual documentation time while ensuring consistency and accuracy.

Read more about how Generative AI Enhances Productivity

AI agents suggest immediate adjustments to assembly lines

Intelligent systems monitor production metrics and generate optimization recommendations for line balancing, resource allocation, and process parameters, improving overall equipment effectiveness and reducing bottlenecks in manufacturing workflows.

Use Case: Pharmaceutical production lines

Pharmaceutical manufacturers are implementing AI-powered batch recipe optimization systems to automatically adjust mixing parameters, monitor batch consistency, and generate compliance reports. These AI systems analyze process data from sensors, instruments, and process controls to identify abnormalities and predict deviations, enabling quick corrective action while maintaining product quality.

6. Digital twin enhancement

Generative AI enhances digital twin capabilities by creating more sophisticated virtual models that can simulate complex scenarios and accurately predict system behavior.

Generative AI helps simulate and improve digital twin models

AI algorithms generate realistic operational scenarios, failure modes, and environmental conditions that digital twins can simulate, providing manufacturers with testing environments that mirror real world complexities and variabilities.

Real-time predictive simulations in virtual environments

Enhanced digital twins powered by generative AI can run thousands of simulation scenarios simultaneously, predicting optimal operating conditions, maintenance schedules, and production adjustments before implementing changes in physical systems.

Use Case: Energy plants, automotive, or smart factories

Siemens pioneered digital twin usage at their Amberg Electronics Plant in Germany, creating virtual replicas of entire production processes that resulted in a 30% increase in manufacturing volume adjustment capability, a 20% boost in productivity, and a 40% enhancement in space efficiency through AI-enhanced simulation and optimization capabilities.

7. Personalized mass production

Generative AI enables manufacturers to offer customized products at scale while maintaining efficiency and cost-effectiveness through intelligent automation and optimization.

Custom orders with dynamic pricing and configuration

AI systems generate personalized product configurations based on customer preferences and requirements, automatically calculating pricing and production timelines while ensuring manufacturing feasibility and profitability for each custom order.

AI-generated variations based on customer data

Machine learning algorithms analyze customer behavior, preferences, and usage patterns to generate product variations that meet specific needs, enabling mass customization without the traditional complexity and cost penalties.

Use Case: personalized furniture or consumer electronics

In consumer electronics, companies like Samsung are implementing personalized AI features across their product ecosystem, creating device configurations that adapt to individual user behaviors and preferences.

Benefits of generative AI in manufacturing

Implementing generative AI in manufacturing delivers measurable benefits across multiple operational dimensions, transforming traditional production paradigms.

Faster time to market

Generative AI accelerates product development cycles by automating design iterations, reducing prototyping time, and enabling parallel development processes. For complex products, this cuts time to market from years to months.

Cost efficiency and resource savings

AI optimization reduces material waste by up to 30%, minimizes energy consumption through intelligent process control, and reduces labor costs through automation, delivering significant cost savings across manufacturing operations.

Innovation and R&D acceleration

Generative algorithms explore design spaces beyond human imagination, generating novel solutions and innovative approaches that drive breakthrough products and new manufacturing processes and accelerate research and development timelines.

Enhanced safety and reduced errors

AI-powered systems eliminate human error in critical processes, predict safety hazards before they occur, and ensure consistent quality standards, reducing workplace accidents and product defects.

Challenges in adoption

Despite numerous benefits, manufacturers face obstacles when implementing generative AI technologies that require careful planning and strategic approaches.

Data security and IP concerns

Manufacturing data contains valuable intellectual property and trade secrets, requiring robust security measures and careful vendor selection when implementing cloud-based AI solutions. Companies must balance AI benefits with data protection requirements and consider on-premises or hybrid deployment models.

Integration with legacy systems

Most manufacturing facilities operate legacy equipment and software systems not designed for AI integration. Successful implementation requires significant investment in system upgrades, API development, and middleware solutions to connect AI platforms with existing infrastructure.

Training workforce for AI collaboration

Manufacturing employees need new skills to work effectively with AI systems, requiring training programs, change management initiatives, and cultural shifts toward human-AI collaboration. Organizations must invest in upskilling programs and address employee concerns about job displacement.

How Folio3 AI can help with AI in manufacturing

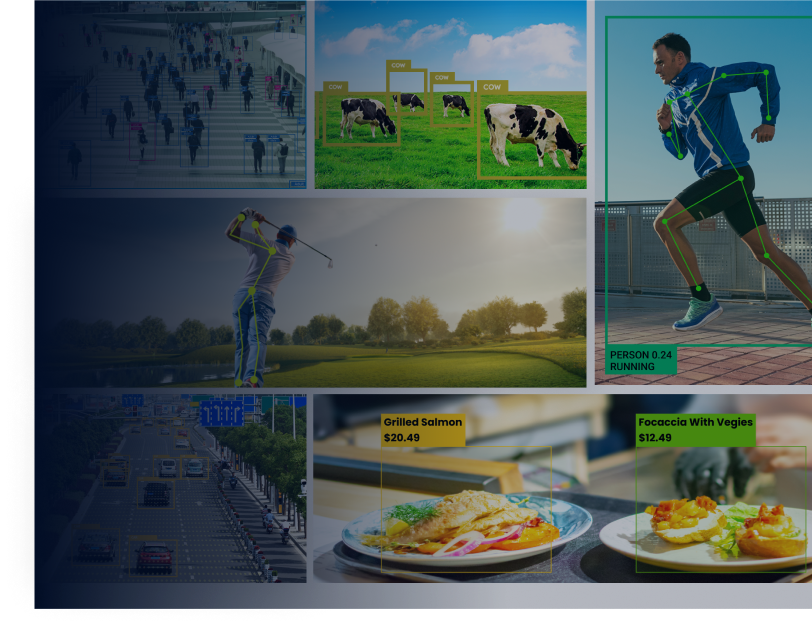

Folio3 AI delivers artificial intelligence solutions specifically designed for manufacturing environments, combining computer vision, predictive analytics, and custom AI development services.

Predictive maintenance & remaining useful life solutions

Advanced AI algorithms analyze equipment data to predict maintenance needs and calculate remaining useful life of components, preventing unexpected downtime while optimizing maintenance schedules for maximum operational efficiency and cost savings.

AI-powered quality control & visual inspection

Computer vision-based systems automate quality assurance processes through visual inspection. They detect defects and faults in production lines while ensuring consistent quality standards and reducing manual inspection requirements.

Custom AI integration & analytics support

Tailored AI solutions integrate seamlessly with existing manufacturing systems, providing spontaneous insights, continuous model training, and analytical support for data-driven decision making across all operational levels and manufacturing processes.

Explore this about how to Integrate AI Into Your App: Experts Insight

How to get started with generative AI in manufacturing

Implementing generative AI requires strategic planning, careful assessment, and phased deployment approaches tailored to manufacturing environments and organizational capabilities.

Assess your current tech stack

Evaluate existing systems, data infrastructure, and integration capabilities to identify gaps and requirements for AI implementation, ensuring compatibility with current operations while planning for future scalability and expansion.

Identify high-impact areas for AI intervention

Focus on processes with repetitive tasks, data-rich environments, and clear ROI potential, such as quality control, predictive maintenance, or design optimization, where AI can deliver immediate and measurable benefits.

Consider building custom AI tools with expert help

Partner with AI development specialists to create tailored solutions that address specific manufacturing needs and integrate seamlessly with existing workflows. Explore Folio3’s AI Manufacturing Solutions to accelerate your AI transformation journey.

FAQs

What is the difference between traditional AI and generative AI in manufacturing?

Traditional AI analyzes and classifies existing data to make predictions or decisions. Generative AI creates new content, designs, or solutions based on learned patterns, enabling innovative applications like design optimization and synthetic data generation.

How much does it cost to implement generative AI in manufacturing?

Implementation costs typically range from $50,000 to $2,000,000, though prices may vary depending on your specific project needs, complexity, and business requirements. Most organizations see positive returns within 12 to 18 months through efficiency gains and cost reductions.

What skills do manufacturing employees need to work with AI?

Employees need basic digital literacy, data interpretation skills, and an understanding of AI capabilities and limitations. Technical roles require programming knowledge, while operators need training on AI-enhanced interfaces and decision-making processes.

How secure is generative AI for sensitive manufacturing data?

Security depends on the implementation approach and vendor selection. On-premises and hybrid solutions offer greater control over sensitive data, while cloud solutions provide advanced security features and compliance certifications from established providers.

Can small manufacturers benefit from generative AI?

Yes, cloud-based AI platforms and SaaS solutions make generative AI accessible to smaller manufacturers through affordable subscription models and pre-built applications that don’t require extensive technical infrastructure or expertise.

Final Words

Generative AI represents a powerful force in manufacturing, offering opportunities to optimize operations, accelerate innovation, and reduce costs. From generative design and predictive maintenance to supply chain optimization and personalized mass production, AI applications are reshaping how manufacturers approach traditional problems.

While implementation requires careful planning and investment in workforce development, early adopters are already realizing competitive advantages through improved efficiency, faster market time, and enhanced product quality.

Laraib Malik is a passionate content writer specializing in AI, machine learning, and technology sectors. She creates authoritative, entity-based content for various websites, helping businesses develop E-E-A-T compliant materials with AEO and GEO optimization that meet industry standards and achieve maximum visibility across traditional and AI-powered search platforms.