Executive Summary:

Using AI-based solutions, the automobile sector can take advantage of AI’s full potential and gather information from a variety of sources and sensors to manage its workforce, manage its inventory, plan its operations, and provide users with safe driving support.

Introduction:

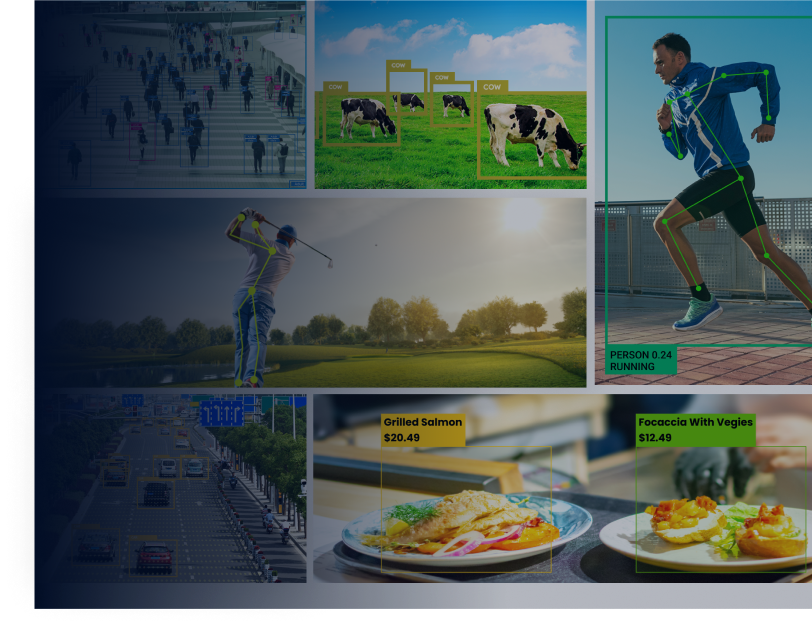

Computer vision applications have shown considerable promise in the automotive sector, both inside and outside the car, such as in production, sales, and after-sales procedures, as well as for advanced driving assistance systems and autonomous driving.

Here is a guide on the advantages of computer vision for scaling and defect detection in the automotive industry.

Key Trends in AI Vision Technology

Numerous applications of computer vision services are found in the automobile sector, including robots and autonomous driving, process optimization in manufacturing, quality issue detection, and connected vehicle services.

- The Computer vision Era

Large neural networks with several hidden layers are called deep neural networks (DNN). The system uses DNNs for feature generation, learning, classification, and forecasting. IoT and AI working together will enable the implementation of scalable, intelligent systems (AIoT).

- The Edge is Nigh for AI’s Future

AI technology and the Internet of Things are combined to create intelligent distributed IoT systems. In addition, machine learning may now be applied closer to the network edge thanks to developments in AI hardware, a notion known as Edge AI. As a result, bandwidth bottlenecks are substantially less likely to occur as systems’ endpoint counts rise.

The ability to do machine learning at the data source and on-device (Edge Intelligence) makes it possible to develop and implement strong computer vision applications for the real world. In addition, it is significantly less likely that adding more system endpoints (edge devices) will result in bandwidth problems.

Computer Vision System Types

Most computer vision services used in manufacturing fit into one of the following categories:

Type 1: Both production line robots and automation systems that perform operations that would otherwise be carried out by human operators reduce human error.

Type 2: Intelligent systems may produce insights, identify problems before they become costly business interruptions, make planning easier, and monitor the work floor and inventories so that quicker, better decisions can be made.

Type 3: Systems for quality control that automatically check for potential manufacturing errors or component flaws during assembly or in the finished product

Computer vision for the Automotive Industry

To assure the quality of the product and the assembly process, automotive manufacturing assembly activities involve visual inspections like scratch identification on machined surfaces, item identification, and selection. The artificial perception of Computer Vision services is quickly rising in prominence due to the development of AI and automation technologies in manufacturing. Computer vision-based modern technologies offer far greater flexibility, reliability, and scalability. In addition, visual inspection duties can be carried out and assisted by AI models, with very little impact on the production environment.

- Automatic Vision System for Detecting Visual Defects

Most consumer returns for defective goods are brought on by aesthetic flaws, frequently in connection with the painting. For example, systems using automatic Computer Vision services may examine the exterior of manufactured parts, such as wheels. Real-time fault identification can be made with the help of multiple cameras positioned above the production line. The systems keep an eye on abnormalities in the wheel coating intensity, including a slight decrease in paint volume, which would indicate an urgent issue with the painting procedure.

- Assembly Line Part Inspection

Computer vision applications for automotive AI vision hold huge potential for part inspection and defect localization. Computer vision techniques are more reliable in finding many flaws. For example, such algorithms attained an accuracy of 95.6% on cylindrical grey shade brakes when trained on a custom-gathered dataset for failure identification using transfer learning.

- Robotics and Smart Devices

High-performance computer vision sub-systems are necessary for robotics. Computer vision is frequently used to control machines by identifying features in camera images. Although near-real-time object identification has already made significant advancements, object tracking still faces many difficulties. Therefore, researchers are developing Computer Vision services to enable self-learning robots that gain intelligence over time.

- Track Tool Movement in Automotive Assembly

The technician must adhere precisely to the specific order in which intelligent systems produce torque levels. For example, visual AI may choose the preferred ranking for the bolts, identify when a torque tool has visited each bolt location, and flag faults in the order of operations on the vehicle assembly line.

- Ergonomic Risk Evaluation

Ergonomic risk analyses contribute to improved occupational health and safety in the car manufacturing industry. Accurate risk evaluations are conducted using computer vision and machine learning techniques applied to digital video analysis. Even in less-than-ideal circumstances, computer vision can simultaneously perform unsupervised ergonomic assessments of numerous workers.

Computer vision used in vehicles

- Autonomous Driving

Machine learning and Computer Vision services and technologies are required for various autonomous driving applications. Processing enormous amounts of data from cameras in conjunction with other sensors (like Lidar) and learning about driving conditions and driver behavior are two key components.;

The benefits of Computer Vision services in the automotive sector are as follows:

- Road Signs Detection in Real-Time

Computer vision techniques recognize traffic signs by detecting their shape and size. Recognizing traffic signs is crucial for computer vision, especially for autonomous vehicles. Other uses for cameras for traffic sign detection include maintaining and managing the assets of highways or improving road safety.

- Scaling via Computer Vision for Defect Detection

Scaling is one of the manual visual assessment’s biggest and most frequent problems. So when you realize that a single inspection may take three control inspectors working two shifts for six days in a row, it is no surprise.

Businesses are more likely to optimize their operations and reach their scaling objectives by incorporating computer vision. As the computer vision tool removes the bottleneck of people quality control inspection, the producers can also expand in other sectors.

Conclusion:

In the automotive sector, Computer Vision services and technologies enhance operational control. Connecting AI vision systems provides the infrastructure to identify and respond to manufacturing problems that might cause expensive company interruptions. By automating manual activities, visual AI makes it feasible to decrease human error, boost operational productivity, and enhance employee safety.

Dawood is a digital marketing pro and AI/ML enthusiast. His blogs on Folio3 AI are a blend of marketing and tech brilliance. Dawood’s knack for making AI engaging for users sets his content apart, offering a unique and insightful take on the dynamic intersection of marketing and cutting-edge technology.