Waste management companies face the same daily struggle, trucks burning fuel to visit half-empty containers while other bins overflow and generate customer complaints. Drivers follow the same routes week after week, and sorting facilities rely on workers who can’t match the speed and accuracy that contracts demand.

With 2.01 billion tonnes of municipal solid waste generated annually and traditional collection methods wasting up to 70% of resources on unnecessary pickups, profit margins stay razor-thin. As municipalities demand better service and environmental accountability, the debate over manual vs AI waste management has shifted from a theoretical discussion to an operational necessity for companies seeking a competitive advantage in modern waste management technology.

What is Manual Waste Management?

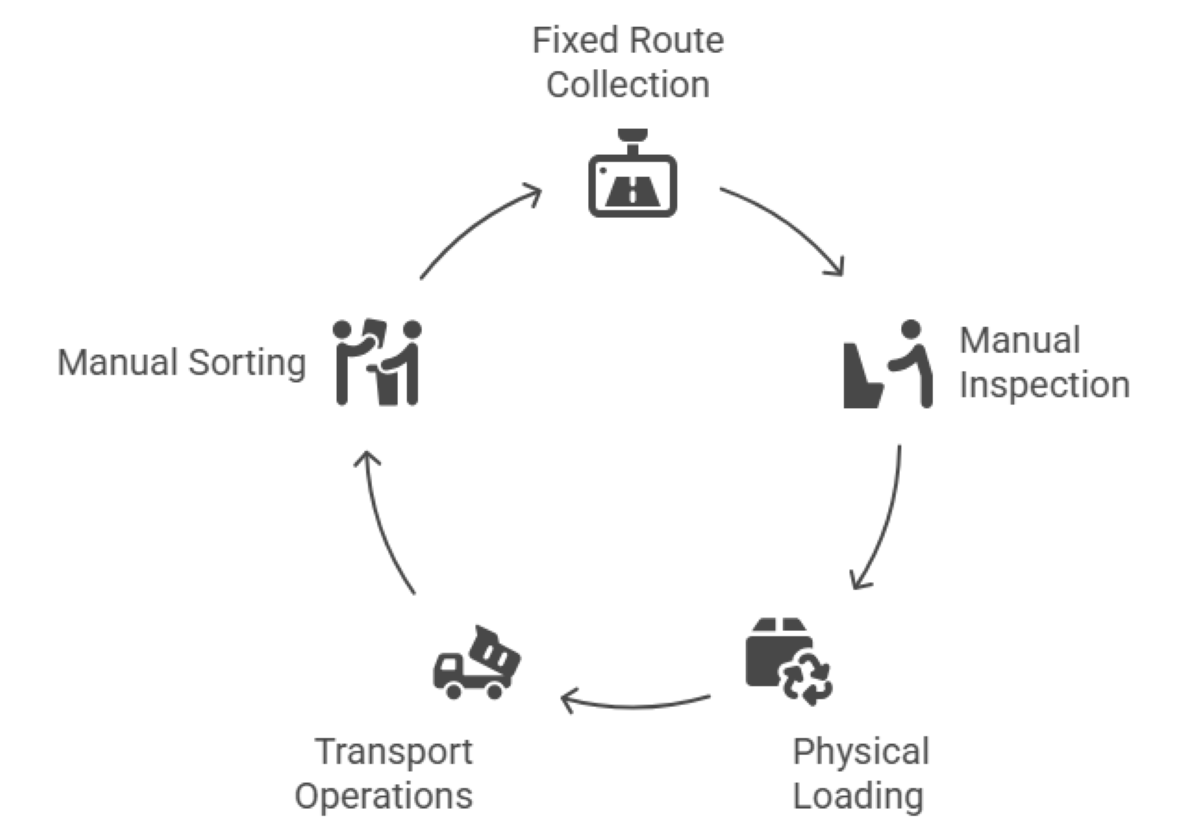

Manual waste management relies on human workers to handle collection, sorting, and disposal processes without automated assistance. This traditional approach uses scheduled routes, manual bin inspections, and human-operated sorting facilities where workers physically separate recyclables from general waste.

Staff members drive predetermined routes, manually check containers, load materials into trucks, and transport waste to processing centers where employees sort materials by hand on conveyor belts.

Process Steps in Manual Systems

Traditional manual waste management follows established operational procedures that depend on human intervention and predetermined schedules for all collection activities.

- Fixed Route Collection: Trucks visit every container following predetermined schedules regardless of actual fill levels.

- Manual Inspection: Workers physically check bin contents and assess waste volume before collection.

- Physical Loading: Staff manually load waste materials into collection vehicles using standard equipment.

- Transport Operations: Materials move from collection points to centralized processing facilities via truck transport.

- Manual Sorting: Employees at processing centers sort recyclables by hand using visual identification on conveyor systems.

Common Use Cases for Manual Systems

Certain operational environments and budget constraints make manual waste management the practical choice for many communities and service areas.

- Developing Regions: Limited technology infrastructure and budget constraints make manual systems more economically viable.

- Small Municipalities: Local governments lack financial resources for significant automated equipment investments and maintenance.

- Rural Areas: Scattered populations benefit from the flexible manual collection over standardized, automated container systems.

- Limited Infrastructure: Areas without reliable power or internet connectivity rely on manual operations for consistency.

- Workforce Availability: Regions with abundant labor find manual systems economically practical and socially beneficial.

Limitations of Manual Approaches

Traditional manual systems face several challenges that impact operational efficiency, cost management, and service quality across waste management operations.

- High Labor Costs: Personnel expenses consume 60-70% of total waste management budgets, creating ongoing financial pressure.

- Sorting Errors: Human mistakes lead to 15-20% contamination rates in the recycling stream, reducing material value.

- Schedule Inefficiency: Fixed routes waste fuel and resources visiting empty containers while missing overflow situations.

- Safety Risks: Manual handling exposes workers to injuries from heavy lifting and hazardous materials.

- Limited Data: Manual systems provide no real-time insights for route optimization or operational improvements.

What is AI Waste Management?

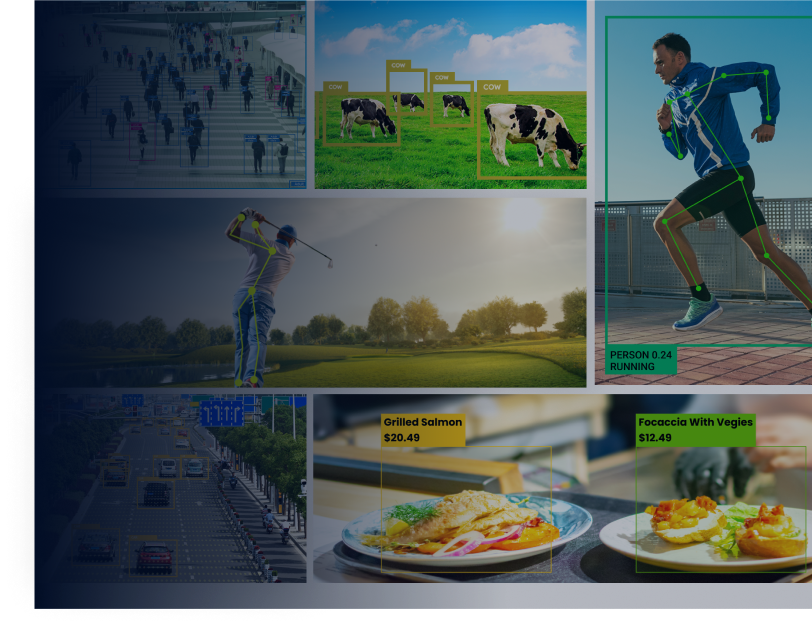

AI waste management uses machine learning, computer vision, and IoT sensors to automate collection, sorting, and route optimization processes. These intelligent systems analyze real-time data to predict waste generation patterns, optimize collection schedules, and improve recycling accuracy through automated sorting.

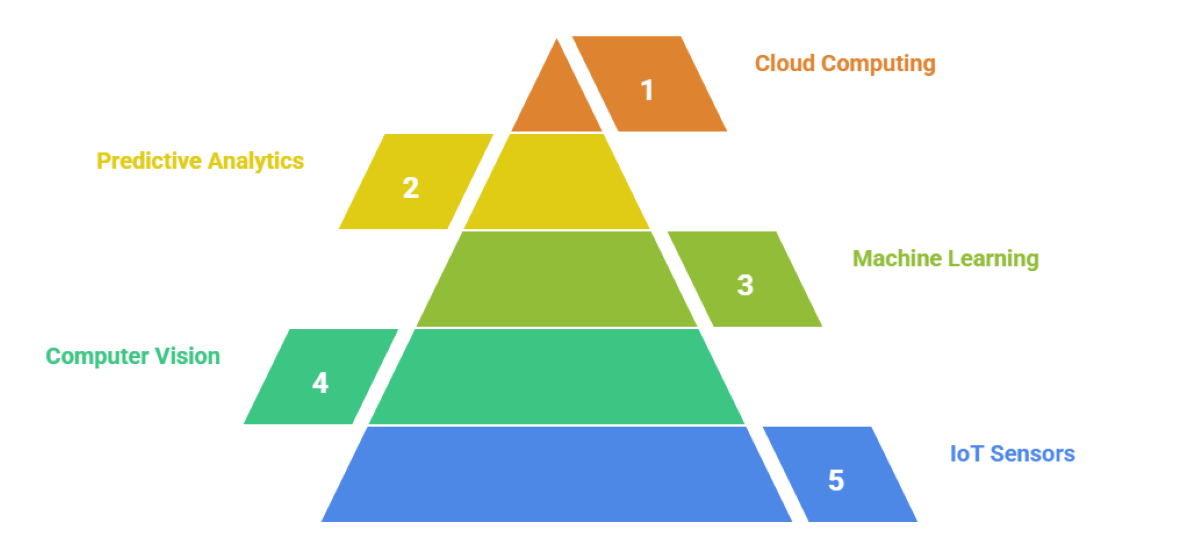

Core Technologies in AI Systems

AI waste management platforms combine advanced technologies, including machine learning algorithms, computer vision, and IoT connectivity, to create intelligent operations.

- Machine Learning: Analyzes historical patterns and real-time data to predict optimal collection timing and routes.

- Computer Vision: Identifies and classifies materials with 95% accuracy compared to 85-90% human sorting rates.

- IoT Sensors: Monitor bin fill levels, temperature, and location continuously for operational insights.

- Predictive Analytics: Forecast maintenance needs, capacity requirements, and seasonal waste generation patterns.

- Cloud Computing: Process massive data streams for real-time decision-making and system-wide optimization.

Smart Infrastructure Components

Modern AI waste systems rely on connected devices and automated equipment that work together to optimize collection, sorting, and processing operations.

- Smart Bins: Transmit fill-level data every 15 minutes, enabling demand-based collection instead of fixed schedules.

- Route Optimization: Software creates efficient daily paths considering traffic patterns, bin status, and operational constraints.

- Robotic Sorting: AI-powered systems process up to 160 materials per minute with superior accuracy.

- Mobile Applications: Provide drivers real-time updates, optimized routing, and collection status reporting capabilities.

- Integration APIs: Connect waste management systems with existing municipal software and enterprise platforms.

Real-World Implementation Examples

Leading technology companies have successfully deployed AI waste management solutions across various markets, demonstrating measurable operational improvements and cost savings.

- AMP Robotics: Operates AI sorting systems in 300+ facilities worldwide, achieving consistent 95% accuracy rates.

- Greyparrot: Reduced manual sampling costs from £4,300 to £17 for equivalent waste composition coverage.

- Ecube Labs: Solar-powered compactors increase bin capacity by 500% while reducing collection frequency by 80%.

- Sensoneo: Deployed 130,000+ connected sensors, reducing unnecessary pickups by 40-60% across multiple cities.

- Recycleye: Achieved 10% output increases on paper lines and 8% purity improvements on aluminum streams.

Manual vs AI Waste Management – Feature Comparison

| Feature | Manual | AI-Based |

| Efficiency | Low – Fixed schedules, human limitations | High – Real-time optimization, 24/7 operation |

| Cost Over Time | High – Ongoing labor, fuel waste | Lower – Reduced collections, automation savings |

| Scalability | Limited – Linear staff increases needed | Highly Scalable – Software scales without proportional costs |

| Data Insights | None – Paper records, manual tracking | Real-time analytics – Predictive insights, trend analysis |

| Environmental Impact | High – Unnecessary trips, poor sorting | Reduced – Optimized routes, improved recycling rates |

Benefits of AI in Waste Management

AI-powered systems deliver measurable improvements across operational efficiency, cost management, and environmental performance that traditional manual methods cannot achieve.

Smart sensors reduce unnecessary collections by 40-60% while automated sorting operates continuously.

- Route optimization cuts travel time by 36.8% through efficient planning.

- Automated facilities achieve payback within 5-7 years through reduced labor costs.

- Smart collection eliminates fuel waste from unnecessary trips.

- Sensors monitor equipment performance to predict maintenance needs.

- Machine learning identifies failure patterns, enabling proactive repairs..

- AI considers bin levels, traffic patterns, and capacity to determine optimal routes, with real-time updates responding to closures and failures.

- Fill sensors trigger collections before overflow, preventing complaints and predictive analytics forecast peak capacity needs.

- Computer vision achieves 95% accuracy, compared to 85-90% accuracy with human sorting.

- Automated systems maintain consistent quality without fatigue.

Challenges & Considerations

Implementing AI waste management requires careful planning to address practical obstacles, including costs, training needs, and organizational change management requirements.

- Technology integration requires additional infrastructure upgrades, as smart sensors cost between $200 and $1,500 each, with city deployments ranging from $50,000 to $100,000.

- Staff need skills in software platforms, sensor maintenance, and data interpretation, with technical teams requiring expertise in IoT and machine learning.

- Connected systems generate data that requires secure transmission, storage, and protection from cyberattacks.

- Traditional companies resist new technologies due to established processes, and employees worry about job displacement from automation.

When Is Manual Waste Management Still Useful?

Despite AI advantages, manual systems remain practical in specific situations where technology adoption faces barriers or operational constraints.

- Low-Budget Rural Areas: Rural communities often find manual collection to be more cost-effective than implementing smart infrastructure, especially in developing regions that lack internet connectivity for IoT systems.

- Temporary Deployments: Construction sites require flexible collection systems that adapt to changing locations. Moreover, emergency response requires immediate deployment without infrastructure setup.

- Disaster Relief Zones: Emergencies prioritize rapid deployment over optimization as damaged infrastructure prevents technology-dependent systems from functioning. In such situations, manual systems operate independently, without requiring connectivity.

Choosing the Right Solution

Selecting between manual and AI waste management requires evaluating operational requirements, financial capabilities, and strategic objectives to achieve sustainable growth.

- Budget and Resource Evaluation: Initial costs vary between manual labor and technology infrastructure. Operating expenses favor AI through efficiency, but the manual has a lower upfront investment. Total ownership includes maintenance and upgrade costs.

- Size of Operation: Large urban areas benefit from AI’s ability to handle high volumes and complex routing. Small communities find manuals adequate for limited waste generation. Mid-size operations often use hybrid approaches.

- Regulatory Requirements: Environmental regulations may require detailed tracking, which favors automated systems. Compliance reporting benefits from AI data collection capabilities. Some jurisdictions incentivize smart technology adoption.

- Long-term Sustainability Goals: AI systems deliver better environmental outcomes through optimization and recycling. Future scalability supports growth beyond the capabilities of manual systems. Carbon reduction commitments may require AI efficiency.

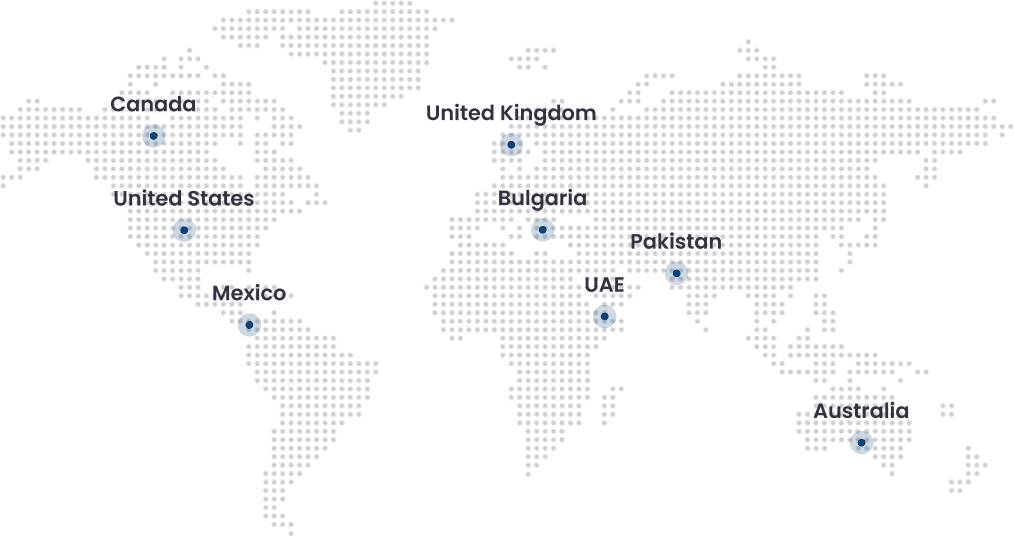

Why Choose Folio3 for AI Waste Management Solutions

Folio3 delivers proven AI waste management solutions that transform operations while ensuring successful implementation and long-term value for growing companies.

- Deep AI & Machine Learning Expertise: With over 15 years of developing AI solutions across industries, Folio3 applies machine learning effectively to waste management systems that predict collection needs, optimize routes, and continuously improve through real-world data processing.

- Custom Solutions That Fit Your Operations: Folio3 develops waste management platforms that align with existing workflows rather than forcing adaptation to rigid software. API-first approach ensures smooth integration with current processes, and flexible architecture accommodates different equipment types.

- Comprehensive Technology Integration: Solutions connect multiple technology layers including mobile applications for optimized crew routing, management dashboards for actionable insights, and ERP system integrations for automated reporting and billing processes.

- End-to-End Implementation Support: Complete project guidance from assessment through deployment and optimization, including staff training programs, continuous system monitoring, and regular updates to keep operations running efficiently long-term.

Frequently Asked Questions

What is the main difference between manual and AI waste management?

Manual waste management relies on human workers for scheduling, collection, and sorting, while AI systems use sensors, machine learning, and automation to optimize these processes. AI provides real-time data and predictive capabilities that manual systems cannot match.

Is AI waste management expensive to implement?

Initial costs range from $10,000 to over $ 200,000, depending on system size. However, AI systems typically achieve payback within 5-7 years through reduced labor costs and operational savings. Manual systems have lower upfront costs but higher ongoing expenses.

Can AI improve recycling rates?

Yes, AI-powered sorting achieves 95% accuracy compared to 85-90% for manual sorting, while computer vision identifies materials more consistently than human workers. Real-world deployments show 10% output increases and 8% purity improvements.

Are there companies already using AI in waste management?

Major companies, including AMP Robotics (300+ installations), Greyparrot (real-time monitoring), and Ecube Labs (smart compactors) have successfully deployed AI solutions. Cities like Amsterdam, Singapore, and Barcelona use AI for route optimization and cost reduction.

Laraib Malik is a passionate content writer specializing in AI, machine learning, and technology sectors. She creates authoritative, entity-based content for various websites, helping businesses develop E-E-A-T compliant materials with AEO and GEO optimization that meet industry standards and achieve maximum visibility across traditional and AI-powered search platforms.