Inventory is the backbone of the modern firm, and potentially its most important asset. – Anita Raj.

In the rapid-paced and dynamic commercial enterprise environment, conventional stock control tactics regularly fall short.

That’s where Artificial Intelligence (AI) steps in, remodeling stock management right into a facts-pushed powerhouse.

AI technology can forecast calls for, optimize inventory degrees, reduce waste, and enhance choice-making, all while saving time and prices.

This weblog explores how AI in stock management revolutionizes companies across industries, enabling them to conform to changing demands and preserve an aggressive aspect.

From predictive analytics to real-time tracking, discover how embracing AI can flip stock control from a task into a strategic advantage.

The Role of AI in Inventory Management

In modern, fast-paced enterprise environments, powerful stock control is critical for preserving operational efficiency and ensuring investors’ satisfaction.

Traditional techniques of inventory control are increasingly inadequate in addressing the complexities of strong supply chains.

This weblog explores the transformative position of Artificial Intelligence (AI) in inventory monitoring and control, highlighting its benefits and implementation strategies.

What is Inventory Management?

Inventory management involves the systematic process of tracking and controlling goods as they flow through the supply chain from providers to manufacturers, warehouses, and ultimately to the factor of sale.

This practice guarantees the right merchandise is to be had in the proper quantities at the right time, balancing expenses whilst meeting patron demands.

Effective inventory control is a logistical necessity and a strategic gain across industries. In retail, for instance, unique stock tracking helps keep away from stockouts of excessive-demand gadgets for peak seasons, ensuring purchaser pleasure and riding income.

Meanwhile, within the healthcare zone, efficient stock management guarantees that crucial resources, inclusive of medicines and clinical systems, are usually to be had, without delay impacting patient care effects.

Similarly, in the automotive industry, just-in-time (JIT) inventory practices reduce excess stock, cut charges, and allow quicker reaction to market demands, maintaining production strains efficiently.

By optimizing stock, businesses can enhance operational efficiency, reduce waste, and improve profitability, making it a necessary characteristic across diverse industries.

Challenges of Traditional Inventory Management

Inventory management is a vital function for any employer, but traditional techniques frequently fall short of addressing the complexities of present-day supply chains.

As businesses scale, diversify, and cater to more and more dynamic consumer demands, old structures work to maintain pace.

These challenges can disrupt operations, boom fees, and hinder standard performance.

Below are some key challenges of traditional stock control and their effect on commercial enterprise approaches:

- Lack of Visibility

Many traditional structures warfare with real-time visibility into inventory levels and inventory movements, making it tough to forecast calls correctly.

Traditional inventory systems frequently fail to provide real-time visibility into stock stages, locations, and movement.

Without accurate and updated records, agencies cannot track inventory throughout warehouses, providers, and retail places.

This loss of visibility hampers choice-making and results in inefficiencies, along with over-purchasing materials or going for walks out of crucial inventory.

For example, a store may also pass over replenishing rapid-shifting items in time, causing stockouts and misplaced sales opportunities.

- Overstocking and Understocking

Inadequate visibility can result in overstocking, resulting in expanded carrying charges and capacity spoilage.

Conversely, understocking can cause misplaced sales and negative client reviews.

One of the most considerable consequences of insufficient visibility is terrible stock stability.

Overstocking leads to high sporting costs, tying up treasured capital, and increases the threat of product obsolescence or spoilage, particularly in industries like meals and liquids.

On the other hand, understocking can bring about neglected sales, upset clients, and damage brand recognition.

For example, an electronics business enterprise underestimating demand for a new product release should lose market share to competitors due to unfulfilled orders.

- Lack of Data Analytics

Traditional systems often depend on manual approaches that do not leverage facts analytics, making it tough to pick out developments and patterns important for knowledgeable decision-making.

Traditional structures regularly rely on guide or semi-automated strategies that do not make use of superior records analytics.

This limits the ability to discover developments, expect demand fluctuations, or optimize inventory replenishment.

Without insights from ancient and predictive analytics, corporations operate reactively in preference to proactively.

A manufacturing firm, for instance, may fail to perceive seasonal spikes in calls, leading to production bottlenecks and supply chain disruptions.

- Complexity

The involvement of more than one stakeholder in conventional inventory tactics can result in time-consuming responsibilities and expanded capability for human mistakes.

Managing inventory via manual tactics involves a couple of stakeholders and time-consuming duties, inclusive of bodily counts and spreadsheet updates.

These workflows are not only hard work-in-depth but additionally liable to human blunders.

Errors in recording or miscommunication among groups can cause discrepancies in stock stages, delayed shipments, or luxurious reordering mistakes.

In sectors like e-commerce, where rapid order fulfillment is critical, such inefficiencies can erode patron acceptance as true with.

- Limited Flexibility

Traditional systems lack the adaptability to reply to actual-time adjustments in calls for or supply chain disruptions.

Traditional systems often lack the agility to respond to actual-time changes in demand or deliver chain disruptions.

Whether it’s a sudden surge in patron demand or an unforeseen supply chain breakdown, corporations counting on inflexible strategies conflict to evolve.

For instance, a clothing retailer may discover it challenging to reallocate stock throughout shops at some point of an income occasion.

This results in excess stock in one region and shortages in every other.

- Integration Issues

Many traditional inventory structures no longer integrate well with other organizational systems, main to operational inefficiencies.

Traditional stock control systems often function in isolation, failing to combine with different vital commercial enterprise systems which include ERP, CRM, or supply chain structures.

This method creates inefficiencies, inclusive of redundant data entry and misaligned workflows, and stops companies from gaining a holistic view of operations.

For example, a pharmaceutical business enterprise may enjoy delays in production planning if its stock records aren’t smoothly integrated with procurement and distribution structures.

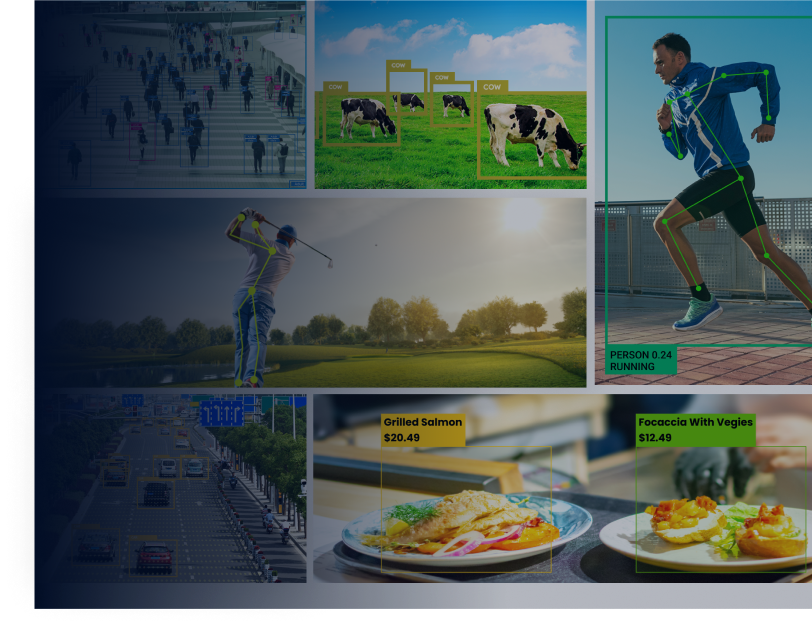

- AI in Inventory Management

AI generation addresses many barriers to conventional stock control by optimizing various parameters in the course of the delivery chain.

It allows organizations to streamline strategies, reduce charges, and beautify basic performance.

AI technology overcomes those traditional challenges by leveraging superior algorithms, predictive analytics, and actual-time data processing.

By automating and optimizing stock control methods, AI permits agencies to enhance decision-making, lessen fees, and decorate operational performance throughout the supply chain.

What Are the Benefits of AI in Inventory Management?

Implementing AI in stock control gives several benefits:

- Data Structuring and Analysis

AI can manage significant quantities of unstructured statistics by cleaning and structuring them for analysis, enabling extra-informed decision-making.

- Demand Forecasting

AI analyzes historical and actual-time records to expect future calls as they should be, assisting companies in maintaining optimal stock ranges.

- Inventory Optimization

AI identifies patterns that humans may additionally neglect, making an allowance for higher categorization and prioritization of inventory based totally on call for dynamics.

- Increased Efficiency

Automation of inventory duties reduces guide intervention, freeing up worker time for extra strategic activities whilst minimizing errors.

- Cost-effectiveness

By preventing overstocking and understocking, AI reduces storage costs and complements overall enterprise efficiency, main to more healthy income margins.

- Supplier Management

AI can examine dealer performance across various metrics, facilitating better supplier selection and negotiation strategies.

AI Inventory Management: Implementation

Successful implementation of AI in stock control calls for careful attention:

- Data Availability:

Access to comprehensive historical and present-day statistics is essential for accurate predictions.

Comprehensive ancient and real-time facts are the inspiration for AI-pushed stock control.

This information includes sales trends, stock actions, purchaser demand styles, and supplier overall performance.

AI systems use this data to generate predictive analytics and optimize stock techniques.

For example, getting access to granular information allows businesses to predict calls for surges during seasonal events, minimizing stockouts or overstocking problems.

- Integration with Existing Systems:

Smooth integration with existing business structures ensures visibility across operations.

Feasible integration with organization systems, inclusive of ERP, WMS (Warehouse Management System), and CRM systems, ensures regular records drift across operations.

Integrated structures enhance visibility, streamline processes, and allow AI algorithms to provide actionable insights.

For instance, AI-driven stock structures included with income structures can dynamically alter stock ranges based on live income statistics.

- Security:

Strong safety features are essential to guard touchy business statistics from breaches.

Robust cybersecurity is critical for defensive sensitive enterprise data at some point in AI implementation.

AI systems process significant quantities of proprietary and client statistics, making them a target for cyber threats.

Implementing superior encryption, getting the right of entry to controls, and compliance measures ensure the safe deployment of AI technologies without compromising sensitive facts.

How are Large Enterprises Leveraging AI for Optimized Inventory Management?

Large firms are more and more adopting AI-pushed solutions for more advantageous inventory control:

- Amazon makes use of superior AI algorithms to forecast calls for and optimize warehouse operations. Its device learning fashions expect shopping developments primarily based on consumer conduct, enabling precise stock stocking and quicker shipping instances.

- Walmart employs AI to automate its replenishment methods, studying extensive datasets to expect customer needs. This method ensures that cabinets are constantly stocked with excessive calls for merchandise, minimizing misplaced income and enhancing the client’s enjoyment.

- AI at Target allows proactive stocking by predicting future demand tendencies. This reduces the chance of stockouts in the course of peak seasons and guarantees that popular items are usually to be had.

- Nike leverages AI for worldwide stock management, balancing inventory ranges across regions to fulfill demand efficiently. This reduces the hazard of overstocking in some locations and understocking in others, making sure of an optimized delivery chain.

Throughput AI for Large-scale Inventory Management

Throughput provides a specialized AI-pushed solution for coping with big-scale stock with efficiency and precision. Its procedure can be divided into three key steps:

- Analysis of SKU/Location Health

Throughput evaluates supply and calls for indicators to pick out capacity risks, consisting of low stock levels or gradual-shifting stock.

By accounting for market fluctuations, it guarantees that the stock aligns with actual-time needs.

- Recommendation of Stock Levels

AI-powered suggestions provide insights into the most appropriate inventory levels for diverse SKUs and places. This ensures that stock is allotted to high-call regions, lowering waste and enhancing transport timelines.

- Buffer Management

Throughput monitors buffer stock consumption against endorsed degrees to minimize waste and mitigate threat publicity. This step ensures inventory remains bendy and conscious of surprising modifications in call for.

Shaping the Future of Smarter Inventory Management

The integration of AI into inventory management marks a paradigm shift, transforming it from a value middle right into a strategic increase enabler. By embracing AI, companies can:

- Enhance operational performance through correct calls for forecasting.

- Reduce charges related to overstocking, understocking, and manual errors.

- Unlock increases possibilities by way of aligning inventory strategies with evolving marketplace developments.

As the AI generation continues to conform, businesses must adapt by making an investment in innovation and building strategies around records-pushed insights.

The future of inventory management lies in smart, agile, and AI-powered structures that redefine performance, pressure profitability, and set new enterprise requirements.

Conclusion:

AI has revolutionized stock tracking and control, presenting companies with exceptional ranges of efficiency, accuracy, and scalability.

By leveraging AI-pushed answers, businesses can limit inventory discrepancies, optimize supply chains, and respond proactively to fluctuating market demands.

These technologies empower agencies to reduce prices associated with overstocking or understocking, beautify customer pride through well-timed product availability, and make records-pushed choices that align with strategic desires.

As industries increasingly undertake AI to stay competitive, the destiny of stock control is set to emerge as more predictive, automated, and responsive.

Embracing AI in stock approaches now not handiest resolves the constraints of conventional strategies but also unlocks new possibilities for innovation and growth, enabling agencies to thrive in an ever-evolving marketplace.

FAQs on The Benefits of AI in Inventory Tracking and Management

AI in inventory management refers to using artificial intelligence technology, consisting of gadget learning and predictive analytics, to optimize stock monitoring, stock tiers, and supply chain operations. It allows corporations to forecast demand, automate replenishment, and improve selection-making based totally on real-time information.

AI enhances inventory monitoring by presenting real-time visibility into inventory stages, locations, and movement. With technologies like IoT sensors and RFID tags incorporated into AI structures, companies can display stock accurately, reduce discrepancies, and make certain seamless operations throughout warehouses and retail places.

The key blessings of AI in inventory management include:

– Accurate call for forecasting.

– Reduced prices through optimized stock stages.

– Real-time inventory monitoring and visibility.

– Improved delivery chain performance.

– Automation of repetitive tasks, decreasing human errors.

Industries that rely closely on inventory control, which includes retail, manufacturing, healthcare, e-commerce, and logistics, see great blessings. For example, shops use AI to expect seasonal demand, at the same time as producers leverage it to decrease manufacturing delays by optimizing uncooked cloth stock.

AI reduces charges by minimizing overstocking, understocking, and manual mistakes. Its predictive competencies ensure that organizations preserve superior stock ranges, reducing carrying prices and stopping lost sales. Additionally, automation of duties like stock audits and replenishment cuts down on hard work prices.

Yes, small groups can adopt AI for inventory management via low-priced, scalable answers tailored to their wishes. Many AI-pushed inventory systems provide cloud-based total services that require minimum premature investment, permitting smaller companies to gain from superior technology without big capital expenses.

Data is the backbone of AI in inventory management. AI structures rely upon ancient income records, real-time inventory data, and market tendencies to generate insights, expect calls for, and optimize inventory levels. The greater correct and comprehensive the facts, the higher the AI device’s performance.

Manahil Samuel holds a Bachelor’s in Computer Science and has worked on artificial intelligence and computer vision She skillfully combines her technical expertise with digital marketing strategies, utilizing AI-driven insights for precise and impactful content. Her work embodies a distinctive fusion of technology and storytelling, exemplifying her keen grasp of contemporary AI market standards.