Executive Summary:

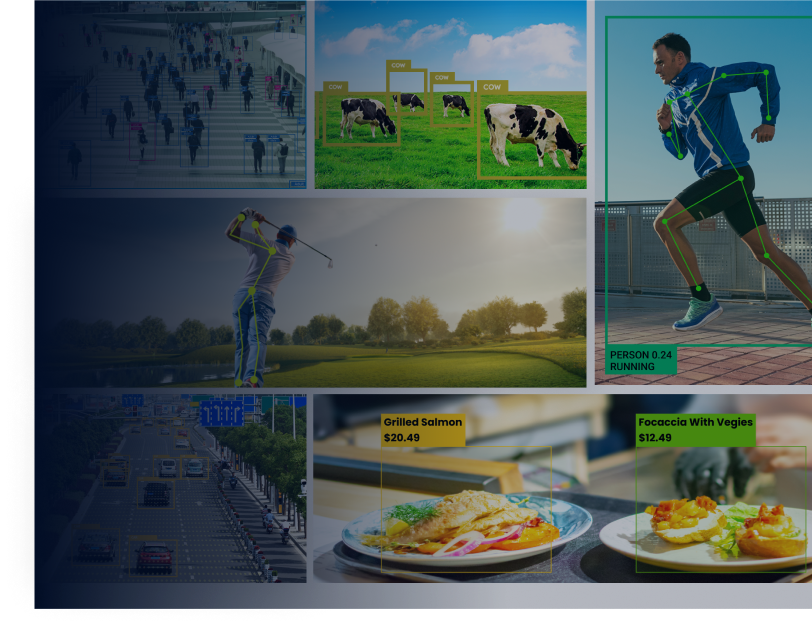

The Role of Food Detection in Supply Chain Traceability, ensuring transparency and safety from farm to fork. By leveraging advanced technologies such as machine learning and computer vision, food detection enables accurate and real-time tracking of food products throughout the supply chain.

Introduction:

The entire food supply chain, from cultivation and harvesting to processing, packaging, and distribution, is a complex network with many stages. Maintaining the food’s quality and safety becomes difficult as it moves through this intricate system.

Solutions for food detection serve as the supply chain’s eyes and ears in this situation. Food detection ensures that every stage is carefully supervised by cutting-edge technology and analytical procedures, delivering crucial information for traceability and food safety management.

The importance and role of food detection in supply chain traceability are examined in this blog, focusing on how they enable precise tracking, improve transparency, and reduce the risk of foodborne illnesses.

Enhancing Transparency with Food Detection Technology:

Using food detection technology to increase transparency will revolutionize the food sector. Knowing where their food originates from and how it has been handled throughout the supply chain is one of the most important issues today’s consumers have, and this solution tackles this issue.

Let’s look more closely at how this critical component of supply chain traceability is accomplished via a food detection solution:

- Accurate Data Collection:

To gather precise and timely information about food goods, food detection solutions use a variety of cutting-edge instruments, including RFID tags, barcodes, and sensors. Due to each item’s unique identification and tagging, it can be followed throughout the whole supply chain.

All crucial data is gathered and recorded from when a product is harvested or manufactured until it reaches shop shelves.

- Blockchain Technology:

Block technology, which offers an unchanging and transparent ledger, is frequently used to store the collected data and provide traceability. Blockchain ensures data integrity while facilitating easy information sharing throughout the supply chain. A new block is added to the chain every time a food product is transferred or processed, establishing a thorough and auditable journey record.

Thanks to this system, all parties, including consumers, have access to reliable information regarding the product’s provenance, certifications, handling procedures, and more.

- Customer Empowerment:

Increased transparency enables people to make knowledgeable decisions about the food they purchase and consume. Shoppers can get comprehensive information on a product’s supply chain journey by scanning a QR code or using a mobile app.

They can substantiate assertions regarding ethical behavior, organic certifications, sustainability, and other topics. This level of transparency promotes ethical consumption and brand loyalty by increasing consumer and brand trust.

Minimizing Foodborne Illnesses Through Early Detection:

Early diagnosis of foodborne infections is essential to reducing their severity and maintaining the security and well-being of customers. From minor discomfort to life-threatening situations, foodborne infections can have serious health effects.

Early detection is essential for finding potential viruses or pollutants in the food supply chain before they might lead to large-scale outbreaks.

Let’s see how this is accomplished through food detection technology:

- Pathogen Detection:

Food detection technology is focused on identifying dangerous bacteria, including Salmonella, E. coli, Listeria, and others that are frequently responsible for foodborne diseases. Food producers may track a product’s supply chain thanks to automated systems and cutting-edge molecular procedures.

Regular testing ensures that potential sources of contamination are found early on at many stages, from farms to processing plants and distribution centers.

- Rapid Testing

Rapid testing techniques are used by food detection solutions to find potential pollutants in food products swiftly. These procedures use various methodologies, including biosensors, immunoassays, and polymerase chain reaction (PCR).

Rapid testing, unlike typical lab-based tests, can provide actionable insights in as little as a few hours or minutes. A typical lab-based test can take days to obtain results. This prompt reaction enables prompt actions and stops tainted goods from reaching customers.

- Real-Time Monitoring:

The role of Food Detection in Supply Chain Traceability is a crucial component of food detection solutions in food processing plants. During food preparation and storage, sophisticated sensors are used to monitor important characteristics, including temperature, humidity, and pH levels.

Alerts can be set off by any deviation from ideal circumstances, enabling operators to take prompt corrective action. This maintains the integrity of the food products and slows the growth of dangerous germs.

Ensuring Compliance and Quality Assurance:

A strong food safety management system is built on compliance and quality assurance pillars. To accomplish these goals, food detection technology integration is essential.

Let’s examine how this technology helps to ensure compliance with rules and uphold high standards along the entire food supply chain:

- Complying with Regulatory Requirements:

Food safety laws are strict and vary between areas and nations. All parties involved in the food sector must abide by these rules. A food detection solution offers real-time monitoring and documentation of crucial data, assisting organizations in meeting these standards.

This covers managing allergens, storage conditions, hygienic procedures, and temperature control during transportation. To pass audits, businesses must show that the appropriate requirements have been followed by keeping correct and current documents.

- Product Claim and Label Verification:

The need for accurate product labeling has increased along with customer awareness. Businesses can use food detection technology to validate product label claims like “organic,” “non-GMO,” and “allergen-free.” Companies can make sure that their product labels match the actual contents of the food items by conducting testing and analyses.

Consumer trust is increased by this level of validation, which also guards against false advertising that can result in problems with the law and harm the brand’s reputation.

- Real-Time Quality Control:

Consistency in product quality is crucial for a brand’s reputation and consumer happiness. Real-time quality control is possible throughout the supply chain thanks to food detection technology. Automated sensors and analytical tools evaluate several quality factors, such as flavor, texture, color, and nutritional value.

Alerts are sent out if established quality criteria are exceeded, allowing for quick corrections to be made to preserve product consistency and satisfy customer expectations.

Preserving Shelf Life:

Beyond safety issues, a food detection solution helps preserve freshness and increase the shelf life of perishable goods. This reduces food waste. Supply chain actors can decide on the best conditions for storage and transportation by monitoring temperature, humidity, and other environmental parameters in real-time.

This addresses a significant sustainability concern the global food business faces by reducing spoilage and food waste.

Conclusion:

Food products travel through the supply chain from farm to fork via various complex procedures. Food detection technology becomes a key ally in ensuring these goods’ security, excellence, and traceability. It is a vital instrument in creating a safer and more sustainable food system because of its capacity to increase transparency, find contaminants, assure compliance, and decrease waste.

The importance of food detection technologies in preserving our food supply and defending customers’ health worldwide will only increase as technology develops.

FAQS:

Q) Can food detection technology validate the claims made on product labels?

A) Yes, food detection technology can verify the veracity of product labels, guaranteeing that statements like “organic,” “non-GMO,” and “allergen-free” are accurate.

Q) How does food detection technology help with supplier verification?

A) By tracking down and confirming the quality and safety of ingredients from vendors, firms can ensure compliance and dependability.

Q) Can food detection technology aid in locating the cause of quality problems?

A) food detection technology supports root cause analysis using a data-driven approach, allowing organizations to identify and solve the root cause of quality or safety problems.

Q) Are all food products susceptible to food detection technology?

A) To ensure food safety overall, food detection technology can be applied to various food products, including fresh produce, processed foods, and perishable goods.

Q) How crucial is food detection technology in relation to customer trust?

A) The food industry relies heavily on consumer trust. By assuring compliance and upholding quality standards, food detection technology fosters confidence, which results in devoted customers and a positive brand reputation.

Dawood is a digital marketing pro and AI/ML enthusiast. His blogs on Folio3 AI are a blend of marketing and tech brilliance. Dawood’s knack for making AI engaging for users sets his content apart, offering a unique and insightful take on the dynamic intersection of marketing and cutting-edge technology.