Manual weighbridge operations create several challenges for businesses. These challenges include inaccurate weight records, slow processes, and costly breakdowns that disrupt logistics operations. The global weighbridge market grows steadily, with experts expecting the weighbridge market to grow at 6.48% CAGR from 2024 to 2032. This growth occurs because companies require more accurate and reliable weighing systems.

Automation transforms logistics and infrastructure worldwide. As a result, automated weighbridge system becomes the key solution for preventing human mistakes. These systems also stop fraud and ensure operations run 24/7.┬Ā

These smart weighing systems represent a huge step forward from traditional manual methods while enabling modern, data-driven vehicle weighing that seamlessly integrates with today’s supply chain operations.

What is an automated weighbridge system?

An automated weighbridge system provides a smart weighing solution. This system eliminates the need for human operators by utilizing intelligent technology. It provides accurate, fraud-proof vehicle weight measurements without requiring on-site personnel.

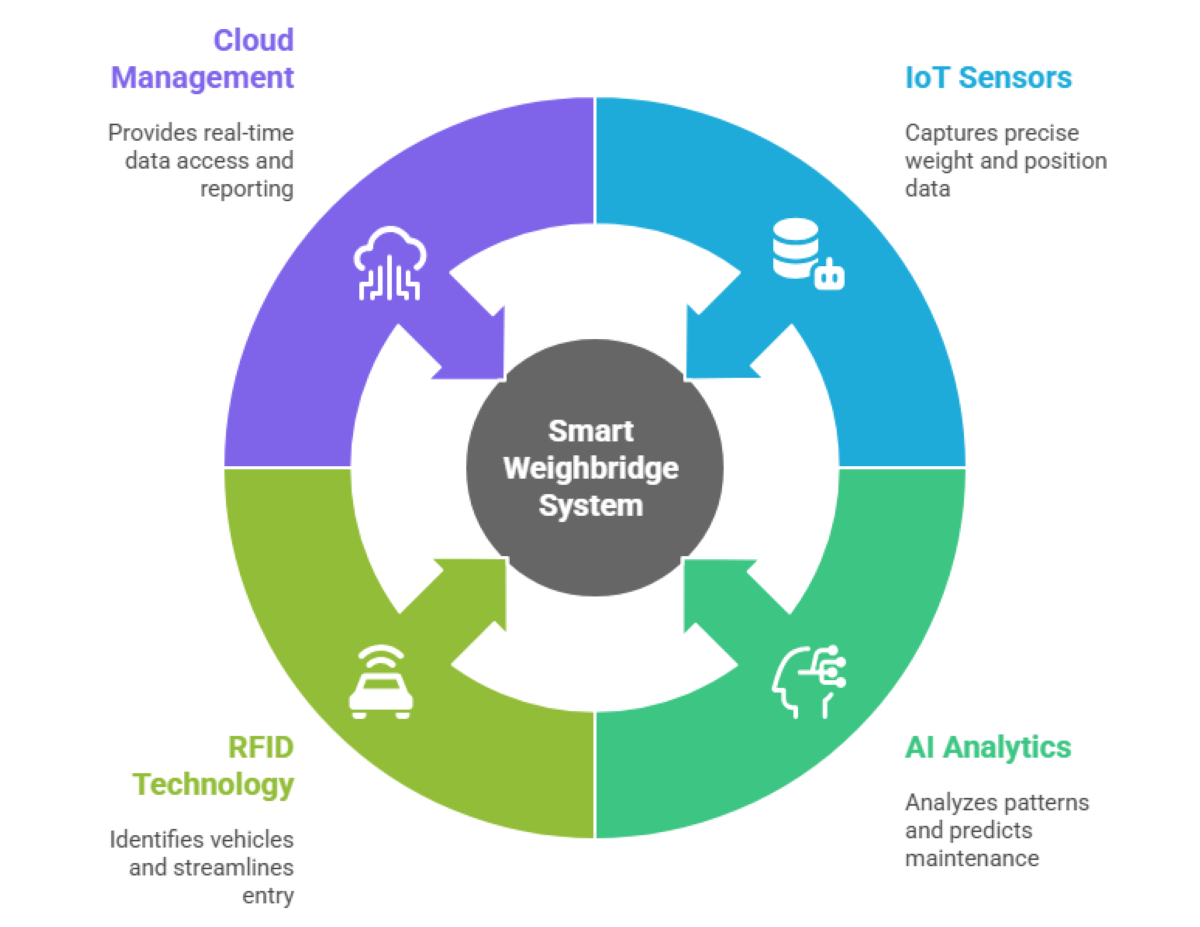

This advanced system utilizes IoT sensors, artificial intelligence, and cloud technology. As a result, it transforms traditional weighing operations into seamless, data-driven processes.

How it works: smart weighing process

Modern automated weighbridge systems combine several technologies seamlessly:

IoT sensor integration

Advanced weight sensors and position detectors capture exact weight measurements. They check vehicle positioning, ensuring accuracy within 0.1%. This provides reliable data collection across all weighing operations.

AI-powered analytics

Machine learning programs analyze weighing patterns and spot unusual activities. They predict when maintenance is needed while automatically creating insights. These insights improve efficiency and prevent fraud through smart pattern recognition.

RFID vehicle identification

Radio frequency technology instantly recognizes authorized vehicles. It automatically retrieves related information and enables seamless entry processes, eliminating manual check-ins and significantly reduces processing time.

Cloud-based software management┬Ā

Real-time data sharing ensures instant access to weighing records. It provides automated report creation, remote monitoring, and complete operational visibility from anywhere at any time.

Core components of the automated weighbridge system

An automated weighbridge system consists of five essential components that work together to deliver accurate weighing results.┬Ā

Precision Load Cells provide the foundation for accurate weight measurement. These high-tech weight sensors distribute across multiple points on the weighbridge platform to capture precise weight data.┬Ā

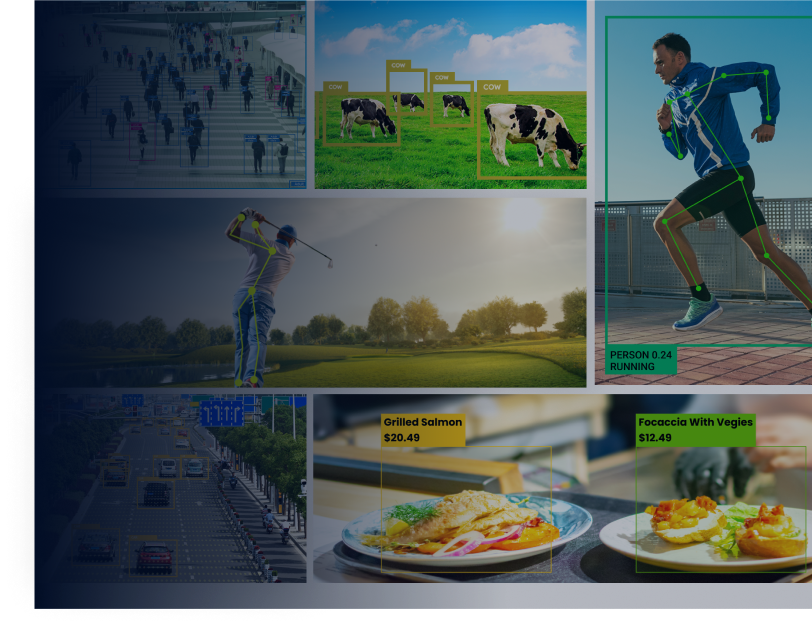

Smart camera systems┬Āmonitor all weighbridge activities through advanced surveillance technology. These cameras utilize computer vision to automatically recognize license plates and capture clear vehicle images.┬Ā

RFID infrastructure enables the automatic identification of vehicles and drivers throughout the weighing process. The combination of RFID readers and tags creates a secure network that identifies authorized vehicles.┬Ā

Programmable logic controllers (PLCs) manage the automated operations of the entire weighbridge system. These industrial-grade controllers coordinate traffic lights, automated barriers, and sensor functions to ensure a smooth flow of vehicles.┬Ā

Advanced software platform integrates all weighbridge components into a unified management system. This cloud-based platform connects with existing ERP and WMS systems to streamline data flow.┬Ā

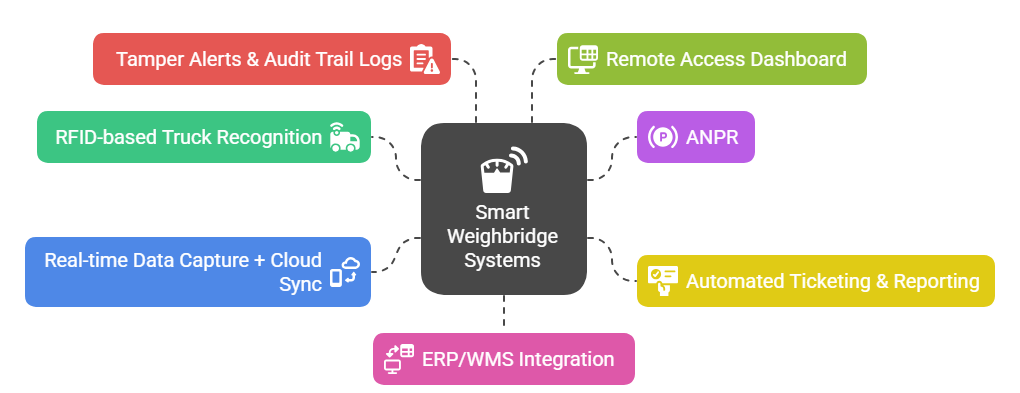

Key features of smart weighbridge systems

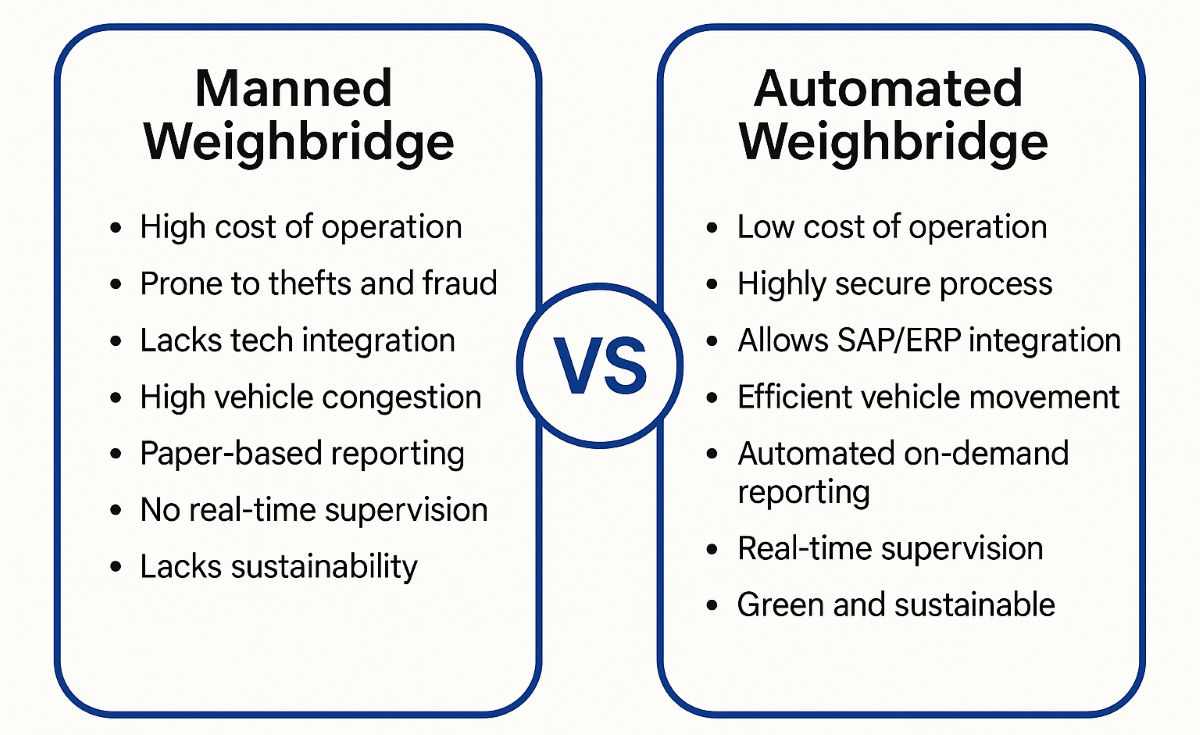

Advanced weighbridge automation software offers comprehensive functionality that transforms traditional weighing operations. These features address the core challenges of manual weighing systems while introducing new capabilities that improve operational efficiency.

RFID-based truck recognition┬Ā

This feature eliminates the need for manual data entry through automatic vehicle identification. This technology reduces processing time by 75% while ensuring accurate cargo tracking throughout the weighing process. The encrypted communication system prevents unauthorized access and maintains complete operational security.

ANPR (automatic number plate recognition)┬Ā

ANPR captures and verifies license plates automatically using computer vision technology. The system cross-references plates against vehicle databases and maintains detailed logs for audit purposes. ANPR provides backup identification when RFID systems experience technical issues or connectivity problems.

Automated ticketing & reporting┬Ā

Auto ticketing replaces paper-based documentation with digital ticket generation. Drivers receive tickets instantly via email or SMS, while billing systems update automatically. The system maintains fraud-proof records through blockchain-verified transaction logs, ensuring complete transparency.

Real-time data capture + cloud sync┬Ā

Real-time data capturing enables the instant transmission of weight data across all connected systems. The moment vehicles enter the weighbridge, weight information appears on monitoring dashboards throughout the organization. Field teams access critical operational data from mobile devices to make immediate decisions.

Tamper alerts & audit trail logs┬Ā

With audit logs, you can monitor weighing operations for unusual patterns or suspicious behavior. Advanced algorithms automatically flag potential security breaches and system manipulation attempts. The system maintains unchangeable transaction records that provide investigation-quality documentation for compliance audits.

Remote access dashboard┬Ā

This option provides 24/7 system monitoring capabilities from any location. Operations teams can troubleshoot issues remotely and simultaneously monitor multiple sites. Customizable analytics dashboards reveal operational insights that support strategic planning and performance optimization.

ERP/WMS integration┬Ā

This integration connects weighbridge systems with existing business software platforms. This integration ensures automatic inventory updates and synchronized financial records throughout the organization. The seamless data flow eliminates duplicate data entry while reducing operational overhead.

Benefits of weighbridge automation for businesses

Automated weighbridge systems deliver several operational advantages that extend throughout logistics and supply chain operations.┬Ā

Accuracy & fraud prevention eliminates human manipulation opportunities through automated measurement systems. The technology achieves measurement accuracy within 0.1% tolerance while maintaining complete transaction records.

Reduced labor dependency decreases staffing requirements by up to 60% through the use of unmanned operations. Organizations can redeploy human resources from routine weighing tasks to higher-value strategic activities.┬Ā

Faster truck turnaround time reduces vehicle processing time from 15 minutes to under 3 minutes. This improvement increases facility throughput capacity by 200% without requiring additional investment in infrastructure.

Better compliance ensures regulatory requirements through automated digital documentation. The system maintains GST compliance and carbon audit readiness while providing real-time monitoring capabilities.┬Ā

24/7 unattended operation enables round-the-clock facility operations without human supervision. This capability eliminates overtime costs and shift scheduling complications while maintaining consistent service levels.

Scalability across multiple sites supports business expansion through cloud-based system architecture. Adding new weighbridge locations integrates seamlessly with existing central management systems.

Real-world applications & industry use cases

Smart weighbridge technology addresses specific operational challenges across diverse industrial sectors. Each industry benefits from automation in unique ways that improve efficiency, accuracy, and regulatory compliance.

Agriculture

Agricultural operations require rapid processing during seasonal harvest periods when time constraints are critical. Grain storage facilities utilize automated weighing systems to efficiently and accurately process farmer deliveries.┬Ā

Waste management & recycling┬Ā

Companies benefit from accurate billing systems that eliminate customer disputes over weight measurements. Automated systems offer route optimization capabilities that enhance driver efficiency and lower operational costs.

Smart Cities┬Ā

Many cities implement weighbridge automation as part of detailed traffic management strategies. These systems monitor vehicle movements in real-time while protecting urban infrastructure from damage caused by overweight vehicles.

Oil & Gas Terminals┬Ā

They handle high-value products where measurement precision has a direct impact on profitability. Automated weighing systems ensure accurate product custody transfers while providing detailed inventory tracking capabilities.

Manufacturing plants┬Ā

Such bodies integrate smart weighbridge technology into quality control and production planning systems. Raw material tracking ensures accurate inventory management throughout the entire production process, from delivery to production.

Construction┬Ā

Projects operate with tight profit margins where material cost control determines project success. Automated weighing provides accurate billing verification, eliminating supplier disputes and tracking material usage against project budgets.┬Ā

Case study: Folio3’s vehicle data intelligence solution

Folio3 AI recently collaborated with Aiden, a California-based startup founded by innovators from Volvo Cars. They developed an end-to-end MLOps service for collecting and analyzing vehicle data.

Challenge

Aiden needed sophisticated machine-learning capabilities to collect sensor data from vehicles. They wanted to make this data useful for various consumers. They needed to manage complex ML workloads efficiently.

Solution implementation

Folio3’s team developed three integrated modules over a 10-month period. They used machine learning, vehicle detection, and fleet management expertise. They created a comprehensive vehicle data intelligence platform.

Vehicle fleet provisioning

Automated AWS IoT Core integration provides unique certificates for secure vehicle communication. It offers smooth onboarding processes that ensure scalable fleet management capabilities.

Data ingestion pipeline

Advanced cloud-based data collection system captures vehicle sensor information. It distributes this information to multiple consumers. It uses optimized data pipelines and real-time processing capabilities.

Consent management

An intelligent consent handling system enables secure data sharing agreements between vehicles and consumers. It maintains privacy compliance and user control over data distribution.

Results

The collaboration enhanced Aiden’s software functionality by 50%. This case study shows how AI-powered vehicle data systems can transform transportation and logistics operations. It demonstrates intelligent automation and data-driven insights.

Trends driving weighbridge automation in 2025

The combination of emerging technologies and regulatory requirements is accelerating the adoption of weighbridge automation, which has affected the global industries notably.

Smart logistics & fleet tracking:┬Ā

Integration with AI-powered fleet management systems enables real-time vehicle monitoring and tracking. It provides route optimization and predictive maintenance, reduces operational costs, and improves delivery performance through data-driven insights.

IoT-based supply chains:┬Ā

Connected sensor networks provide end-to-end visibility. They enable predictive analytics and automated decision-making, integrating weighbridge data with broader supply chain intelligence for optimized logistics operations.

Government mandates

┬ĀRegulatory requirements drive the adoption of automation through the need for digital documentation. E-invoicing compliance and real-time tax reporting requirements increase demand and ensure transparency┬Ā

ESG reporting requirements

Environmental, social, and governance requirements necessitate accurate carbon footprint tracking. They require sustainability reporting and resource optimization, demonstrating corporate responsibility.┬Ā

AI + computer vision

Advanced AI in transportation enables the automatic classification of vehicles. It provides cargo type identification, detects unusual activity, and improves operational efficiency through intelligent pattern recognition.┬Ā

Frequently asked questions

Q1. What industries benefit from automated weighbridge systems?┬Ā

Logistics, agriculture, manufacturing, mining, waste management, and construction industries gain significant advantages. Any operation that requires accurate vehicle weighing benefits from the precision and efficiency improvements that automation offers.

Q2. Can the system work in extreme weather or remote locations?

┬ĀYes, modern systems feature weatherproof components and edge computing capabilities. They operate reliably in temperatures from -40┬░C to +70┬░C with minimal connectivity requirements.

Q3. Is ERP integration possible with older software?┬Ā

Most automated weighbridge systems offer API connectivity and standard protocols. Legacy system integration is achievable through middleware solutions and custom connectors.

Q4. What’s the ROI for weighbridge automation?┬Ā

Typical ROI ranges from 18 to 24 months through labor cost reduction, fraud prevention, and efficiency gains. Many organizations see 200-300% productivity improvements within the first year.

Q5. How does unmanned weighing improve security?

Digital authentication, encrypted data transmission, and fraud-proof logging eliminate opportunities for human manipulation. Automated systems provide superior security through technological controls rather than procedural compliance.

Laraib Malik is a passionate content writer specializing in AI, machine learning, and technology sectors. She creates authoritative, entity-based content for various websites, helping businesses develop E-E-A-T compliant materials with AEO and GEO optimization that meet industry standards and achieve maximum visibility across traditional and AI-powered search platforms.