Since 2012, advancements in technology have greatly transformed the way modern manufacturing works. Automation plays a significant role in streamlining how goods are produced. However, with the rise of generative AI in manufacturing, that change is only going to accelerate.

Despite popular belief, generative AI is not only about automating repetitive tasks. It’s also about creating new models and designs that push the boundaries of current practices, especially in manufacturing.

With the help of generative AI services, manufacturing can enter a new era where thousands of potential configurations are iterated within seconds for a specific produced part, and results are predicted within the blink of an eye.

Thus, the rise of generative AI in manufacturing represents a significant leap toward the future of intelligent and autonomous production. Let’s see how generative AI can bring a change to the manufacturing industry.

Use Cases of Generative AI in Manufacturing

Generative AI brings efficiency and innovation to the manufacturing industry across various stages of the production process. Whether it’s product design or the simple task of predicting an equipment failure, it’s right there, generating solutions to problems that were once considered unsolvable.

Let’s explore some diverse use cases of generative AI services in action:

Generative AI brings efficiency and innovation to the manufacturing industry across various stages of the production process. Whether it’s product design or the simple task of predicting an equipment failure, it’s right there, generating solutions to problems that were once considered unsolvable.

Let’s explore some diverse use cases of generative AI in action:

-

AI-Driven Product Design

Generative AI can augment a range of product designs simply based on the materials, input specifications, and functional requirements. With this kind of help, it’s easy to speed up innovation and reduce development costs.

Generative AI also simulates real-world scenarios to improve designs for performance and strength. It analyzes virtual prototypes to see if they are ready for manufacturability. Furthermore, it can personalize products based on individual customer preferences. This creates a unique experience for all customers who prefer personalized products.

-

Predictive Maintenance AI Solutions

AI can analyze machine sensor data to identify early signs of wear and tear. This technology predicts potential failures to avoid any errors before they occur. This type of advanced approach improves proactive maintenance and reduces production losses.

Generative AI in manufacturing helps continuously monitor production lines. Performance optimization and resource utilization are easy with the help of suggested real-time adjustments.

-

Supply Chain Optimization

Generative AI can analyze market trends and optimize supply chain efficiently. It predicts future demand with much better accuracy than any survey can provide. With the help of customer data, it optimizes inventory levels and reduces waste to ensure materials are available when needed.

The same technology also has the power to optimize logistical routes and take factors like weather, traffic, and vehicle capacity into account. Furthermore, it helps improve delivery efficiency and minimize transportation costs as much as possible.

-

Cybersecurity Enhancements

Generative AI can analyze security logs and detect any suspicious activities. This helps quickly identify any potential threats to the system and alert the right personnel for investigation. This type of technology is much faster than manual monitoring and even learns from past incidents to improve threat detection accuracy.

Moreover, generative AI can help design and implement advanced security measures. It helps prevent potential cyber-attacks and detect anomalies in data patterns.

-

Sustainability Optimization

Generative AI helps optimize energy consumption in manufacturing plants, analyze production data, and identify areas for improvement. It suggests ways to reduce waste and increase the use of renewable energy sources.

Furthermore, it predicts potential environmental hazards and suggests how to prevent them. This technology can be used to optimize supply chain processes and minimize the overall carbon footprint.

Real-Life Examples of Generative AI Integration

Airbus

Airbus collaborated with a design software to optimize the design of aircraft components. It was possible, all thanks to generative AI solutions! This approach resulted in the creation of lighter, fuel-efficient parts, reducing the weight by 15% without compromising structural integrity.

The AI-driven designs showcase the potential of generative AI services in shaping the future of aerospace manufacturing, driving efficiency and sustainability.

Unilever

Unilever uses generative AI in manufacturing to design personalized toothpaste formulations tailored to individual oral health needs. This move away from the one-size-fits-all approach allows Unilever to offer bespoke products, addressing specific customer requirements.

The integration of generative AI in product formulation exemplifies how AI has changed personalization in consumer goods manufacturing.

Ford

Automaker Ford implemented generative AI for predictive maintenance, anticipating equipment failures before they disrupt production. This proactive approach resulted in a remarkable 50% reduction in downtime.

By implementing AI applications in the manufacturing industry for maintenance and predictions, Ford exemplifies how AI enhances operational efficiency and ensures smooth manufacturing processes.

Michelin

Michelin, a leader in the tire industry, is modernizing manufacturing through generative AI to optimize tire designs. The technology assists in creating designs that enhance performance, durability, and fuel efficiency.

Michelin’s use of generative AI showcases its applicability in the intricate process of tire manufacturing, emphasizing its role in driving innovation and improving product quality.

Benefits of Generative AI in Manufacturing

Generative AI development services are driving unprecedented efficiencies, and we are witnessing it firsthand. From elevating design capabilities to optimizing production cycles, nothing is impossible for this technology now. Let’s delve into the integration of generative AI in the manufacturing industry, which offers numerous benefits, such as:

Design Optimization

Innovative manufacturing with AI redefines design, crafting efficient products, minimizing waste, and enhancing performance. It helps reduce manual labor and time-consuming processes in design optimization.

Manufacturers produce lightweight components that are equally robust to their heavier counterparts. Moreover, the use of advanced algorithms in generative AI enables the creation of designs for complex geometries.

Predictive Maintenance

The technology offers predictive maintenance and anticipates equipment failures with ease. This proactive approach optimizes production schedules. It also saves costs that would otherwise be incurred for emergency repairs.

By analyzing historical data and making predictions, generative AI predicts potential equipment failure. This benefit is important for the manufacturing industry because it helps plan for maintenance activities in advance.

Personalization

AI-driven manufacturing processes offer personalized solutions. They are tailored to individual customer preferences and requirements, improving customer satisfaction and loyalty. This personalization also extends to the production process itself.

Efficiency Improvement

By automating tasks done by humans, generative AI in manufacturing minimizes human error. It also increases efficiency in production processes and enables manufacturers to optimize material usage and reduce waste.

Additionally, it analyzes data from various sources to identify areas for improvement. This data-driven approach allows manufacturers to make informed decisions.

Streamlined Workflows

Generative AI services enable manufacturers to streamline workflows. It helps them optimize processes, ultimately leading to enhanced productivity. Generative AI helps identify bottlenecks in the production process and suggest ways to overcome them.

Moreover, it assists personnel in automating repetitive tasks, freeing up human resources to focus on more complex and critical tasks.

How to Implement Generative AI in Manufacturing?

Generative AI has already proven its value in product design, predictive maintenance, and personalized solutions. But how can manufacturers implement it? Here’s a step-by-step guide to help you integrate best generative AI solutions into your manufacturing processes:

Step #1 – Define Your Needs

Before diving into AI, identify specific pain points and desired outcomes—whether it’s design innovation, predictive maintenance, or supply chain efficiency. This will help you focus on what type of generative AI solution is best suited for your business success.

Step #2 – Gather and Organize Data

Gather and organize high-quality data relevant to your chosen application. Invest in data cleaning to ensure reliable results. The better the data, the more accurate and effective your generative AI models will be.

Step #3 – Choose Your Partner Research

There are various generative AI providers; choose one that aligns with your needs, budget, and goals. Collaborate with them to develop a customized solution. This can also help you understand the technicalities of implementing AI in manufacturing.

Step #4 – Integrate and Test

After choosing your partner, integrate the generative AI tools into your existing systems. Test the solutions to ensure they meet desired outcomes. Work closely with your partner to fine-tune the model as needed.

Step #5 – Train Your Team

Provide training for employees on how to use and benefit from the Generative AI tools. Encourage adoption and feedback. This will help your team understand the potential of AI and how to incorporate it into their work.

Step #6- Scale Up

Once you’ve seen success in your chosen application, consider scaling up to other areas of your manufacturing process for further optimization. Continue to gather data, fine-tune the model, and train your team for continuous improvement.

AI applications in the manufacturing industry offer countless benefits by revolutionizing design and creating new products, either from raw materials or components.

What Could Be the Challenge in Generative AI Adoption?

Generative AI integration offers numerous benefits in manufacturing but comes with a set of challenges. Companies may face these challenges when implementing this technology. Some of the most critical challenges are:

Data Availability and Quality

One of the requirements of generative AI is to gather massive amounts of quality data. However, many manufacturers may struggle with either obtaining or organizing such data. This can greatly affect AI algorithms and limit manufacturing processes.

Cost

Integrating generative AI services may come at a significant cost for small and medium-sized manufacturers. The application of AI or machines is expensive, and further, we need a skilled professional to implement it, which can add to the overall cost. This can make it difficult for smaller companies to adopt this technology, giving larger corporations an advantage.

Resistance to Change

Any technology equipment needs constant changes and improvements; this will be a complex situation for employees who are used to old methods. It can be challenging for companies to fully integrate generative AI into their processes and achieve the desired results.

Regulatory and Privacy Considerations

We know that technology collects data of any form, but there are regulatory considerations that manufacturers face. Companies must ensure their customer concerns regarding the security of data and ethical standards are addressed to avoid legal or reputational repercussions.

Keeping Up with Advancements

Technology is constantly changing, especially AI impact on industrial manufacturing. This means that companies must continuously invest in updating their AI tools to stay competitive in the market.

Future Trends Of Generative AI in Modern Manufacturing

With the increasing use of technology, it’s no surprise that generative AI will continue to shape and transform modern manufacturing. Here are some future trends of generative AI to watch out for:

AI-powered Supply Chains

As manufacturers want efficiency and cost-effectiveness, AI-powered supply chains will help in real-time data analysis and capabilities to optimize processes and reduce waste. AI can help automate inventory management, forecasting demand, and logistics management. This will result in faster response times, reduced costs, and improved supply chain transparency.

Collaborative Robots

Human tasks, along with collaborative robots, will change the methods of manufacturing. Collaborative robots can work hand in hand with humans, making assembly and packaging more efficient. With AI-powered learning capabilities, they can also adapt to new tasks quickly.

Smart Factories

Factories incorporating AI and IoT technologies will be highly automated in complex manufacturing products. It includes equipment monitoring, predictive maintenance, and real-time optimization of production processes. AI-powered sensors can collect real-time data, providing insights for better decision-making and improving overall production efficiency.

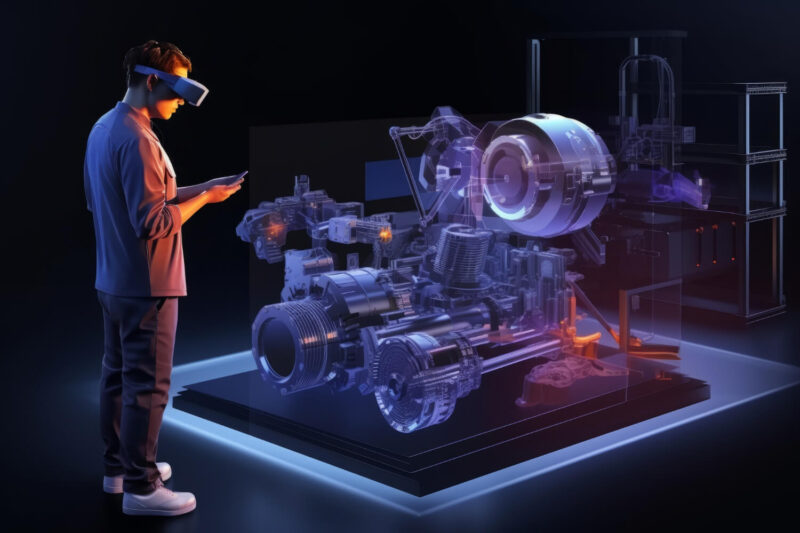

Augmented Reality (AR)

AR technology can assist manufacturers in training employees, troubleshooting issues, and identifying improvement areas. With AR, workers can have virtual training sessions and receive real-time instructions during complex tasks. This will reduce the time needed for training and improve overall quality control.

Conclusion

Generative AI is not just a tool; it is a helpful hand that makes manufacturing thrive on creativity and efficiency. We can see that the impact of generative AI on modern manufacturing highlights its transformative influence.

From optimizing designs like aircraft components to predicting equipment failures, it has extended beyond mere efficiency, pushing sustainable practices, democratizing innovation, and creating a synergistic partnership between humans and machines.

Looking ahead, the next few years look promising as products adapt to individual needs and give a new look to the manufacturing processes with generative AI.

Frequently Asked Questions (FAQs)

How Does Generative AI Improve Manufacturing Efficiency?

Generative AI improves manufacturing efficiency by optimizing designs, predicting maintenance needs, and streamlining workflows. It minimizes material waste which helps with cost savings.

What Are Some Challenges in Adopting Generative AI in Manufacturing?

There are many challenges in adopting generative AI for manufacturing. These include skill gaps, data quality concerns, trust issues, initial implementation costs, and workforce fears.

Which Manufacturing Sectors Benefit Most from Generative AI?

Aerospace, consumer goods, automotive, and medical manufacturing sectors are just some industries that benefit from generative AI.

How Can Generative AI Enhance Product Design and Innovation?

Generative AI has changed product design by optimizing configuration and predicting failures. It helps in innovation by suggesting novel designs and democratizing the creative process.

What Role Does Data Play in Generative AI for Manufacturing?

Data is important in diverse platforms where generative AI helps learning and decision-making. High-quality data is needed to ensure reliable AI outputs.

Dawood is a digital marketing pro and AI/ML enthusiast. His blogs on Folio3 AI are a blend of marketing and tech brilliance. Dawood’s knack for making AI engaging for users sets his content apart, offering a unique and insightful take on the dynamic intersection of marketing and cutting-edge technology.