The concept of computer vision has existed for a long time. Automation has always held many computer vision applications for machine learning.. Whether it be processing social media traffic and trying to surface actionable insights or targeting consumers based on past purchases, automation through computer vision is a dream for any AI developer. In this piece, we deliver a brief introduction to computer vision as well as a breakdown of its history, best uses in manufacturing, and then some examples of computer vision in a building.

Definition

Computer vision is a branch of computer science that focuses on enabling computers to see and therefore, visually identify images to process them as text-based information. It functions in many ways the same as human vision and then provides an appropriate output based on the (visual) input. In short, you impart human intelligence and the ability to solve the problem in the context of an Artificial Intelligence (AI). The computer must understand what it sees and then complete the suitable analysis or required action accordingly.

As mentioned earlier, the goal of Computer Vision as a concept is to mimic human vision by putting digital images through three main processing components, executed one after the other:

1. Image acquisition

2. Image processing

3. Image analysis and understanding

History

In the late 1960s, the concept of computer vision started at the university level. The pioneers of AI envisioned a system that could mimic the human visual system and thereby grant robots one more tool in aiding their decision-making abilities.

What differentiates computer vision from the predominant field of digital image processing at that time was a need to extract 3D structure from an image aimed at comprehending the exact details within that photograph besides what is available in the foreground. By the 1970s, developers had begun to lay the foundations for many of the computer vision algorithms available today. Includes extracting parts of an image, line labels, non-polyhedral and polyhedral modeling, object representation as interconnections of smaller assemblies, optical flows, and motion estimations.

In more recent work, feature-based methods of computer vision have arisen coupled with machine learning applications and complex optimization frameworks. The growth of Deep Learning techniques has further advanced the field of computer vision.

Examples

Autonomous Vehicles

Self-driving cars as well as the regular variety use an array of visual input based sensors to understand the world around them and thereby make decisions for the car’s performance.

Facial Recognition

Businesses and personal electronics all use facial recognition for security. Facial recognition is a classic example of how a computer learns o recognize visual cues.

Furthermore, facial recognition can also extend (in a manner of speaking) to animals. The Zoological Society of London (ZSL) uses AutoML to recognize known species of animals and identify new ones from a vast array of visual data from camera traps around the world and place estimates on population size.

Google Cloud is capable of identifying species from thousands of images quickly and trains new ML models using ZSL’s archival photos. In the future, it could even enable real-time tracking of the world’s biodiversity.

Image Search and Object Recognition

Several systems use the data vision theory to identify objects that exist within a digital image. It allows you to search through extensive catalogs of images, and also extract information out of the photos.

For example, the google translate app has done wonders for bridging the gap between people speaking different languages. Using computer vision, all you have to do is point your camera to the words and let the app work its magic. The app will tell you precisely what it means in your preferred language. The results are almost instant by using Optical Character Recognition (OCR) to see the image coupled with augmented reality to generate an accurate translation (with context). Most PDF readers come with this feature, as well.

Robotics

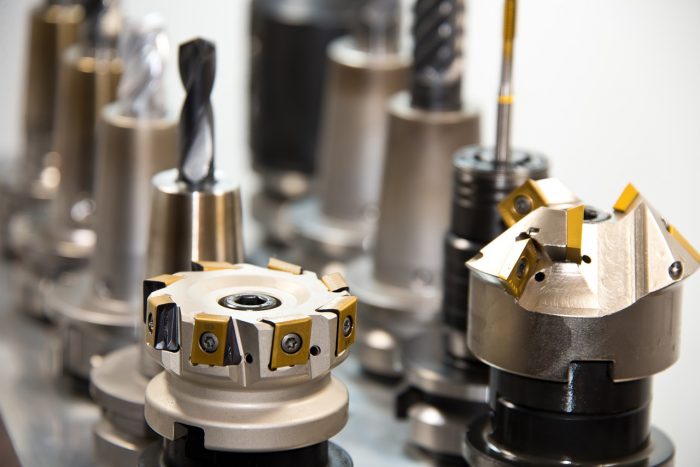

A lot of robotic machines, especially in manufacturing, need to see what’s around them to perform the task at hand. In production, robots are often used to inspect entire assembly tolerances by visually gauging them.

Health and Medicine

Folio3’s Breast Cancer HER2 Subtype Identification was developed to supply an automated pipeline for cell segmentation and spot counting through a Computer Vision-based analytical-aid for the Fluorescent In-Situ Hybridization test. The company developed a computer-guided assistance system that allows technicians to perform the analysis more quickly and accurately while enabling them to digitize and store the images for later usage.

How Computer Vision Can be Used in Manufacturing

Computer vision has many applications in manufacturing including, but not limited to, predictive analytics of machinery, quality control for products, health and safety, and accurate assembly of components. Major businesses in all locations have adopted production and management systems aided by computer vision. Tesla uses sensors to outfit its vehicles for the delf-driving function as well as accident prevention. Kawasaki Heavy Industries uses machine vision to accurately assemble each component of the hydraulic pumps used in heavy machinery. Mining companies use computer vision aided monitoring systems to closely monitor drilling equipment to identify defects and other damage before they can cause an accident.

One of the more recent fields to use computer vision is 3D printing. Computer vision additive manufacturing uses helps maintain the integrity of the build by analyzing visual data and correcting flaws in real-time. The list can go on an on, but a few specific examples are detailed in the following section:

7 Examples of Using Computer Vision in Manufacturing

Additive Manufacturing

The process of manufacturing that builds 3D objects by adding layers of material is known as additive manufacturing regardless of the type of substance.

Computer vision additive manufacturing is the use of a computer, 3D modeling software (Computer-Aided Design or CAD) and machine vision to combine the output data from the layering machine with the visual input data to accurately reproduce the design.

Predictive Maintenance

Predictive Maintenance is critical for businesses that rely on machinery for assembling physical components and or providing services. If these machines were to fail mid-operation, it could spell disaster for the company’s reputation and therefore, cash flow.

Therefore, computer vision in manufacturing (specifically predictive Maintenance) is the system by which machine learning and IoT devices monitor incoming data from machinery and sometimes individual components through sensors. The sensors identify signals that trigger alerts informing you to take corrective action before an asset is lost entirely, or there is an accident.

Package Inspection

It is sometimes imperative for pharmaceutical companies to tally the number of tablets and capsules that are going into any form of packaging. Computer vision for quality control in automated manufacturing systems can help significantly in this task by checking for broken or partially formed tablets. As the medication makes its way through the production line, photos are taken and transferred to a dedicated computer that processes the image using a set of established algorithms designed to check if the tablets have the right color, dimensions, and shape.

Reading Barcodes

It is difficult for humans alone to identify, understand, and process barcodes at the scale we use them in our daily lives. Every single trip to the grocery store adds to this count. The human eye cannot reach the level of accuracy that an automated system might achieve. For speed, you will have to use machine learning coupled with computer vision to analyze the barcodes.

For example, most handheld devices, such as cell phones and mobiles, are becoming smaller and smaller. Meaning that the parts required to assemble them are also becoming smaller. Manufacturers require Printed Circuit Boards (PCBs) that can fit inside these tiny bodies, but manufacturing them is difficult. “Panelization” is the process used to produce several identical circuit boards on one large panel after which a machine separates each circuit. The final testing phase uses a machine vision-based solution (e.g., groups) to read the barcodes on each item to look for defects and any problems in printing.

Product and Components Assembly

Manufacturing plants for high volume and precision products have to ensure that products and components that come off the assembly/production line conform to the strict quality and safety guidelines set by the regulatory authority. Computer Vision-based systems (e.g., Acquire Automation) help businesses guarantee that their products and components are assembled to the standard.

For example, Acquire Automation implements machine vision that permits manufacturers to inspect bottles in a complete 360-degree view to verify that products are placed in the correct packaging as well as other critical attributes such as:

· Cap closure/seal

· Position

· Label

· Print quality, and much more!

Defect Reduction

Companies, justifiably, want components that come off their production line to be error-free. Achieving this at any significant scale can bring several problems for manual efforts. Machine vision, on the other hand, is the ideal technology to help businesses automate a solution to this problem.

WebSPECTOR is a surface inspection system that can identify defects, store photos as well as any accompanying metadata related to the image. As items move along the production line, any errors are classified according to type and then a grade to gauge the severity of the problem.

With this kind of information, companies can differentiate between the many types of defect that occur and implement the correct procedures and policies. For example, manufacturers can follow a process that stops the production line at a certain number of identified effects.

Improving Safety

Machine vision is not restricted to just production lines in manufacturing plants. Machine vision is also used in more diverse settings such as mines and large scale construction. For example, Komatsu Ltd, a leading UK based manufacturer of construction and mining equipment, recently announced its intention to partner with NVIDIA and its “cloud to edge” tech.

A combination of real-time, live feed from cameras, and video analytics algorithms allow the equipment to operate with greater efficiency and with improved safety. The idea is to use deep learning-based AI to track the movement of people and predict where the machines are going to be to avoid dangerous interactions. With as much as 10,000 injuries occurring on construction sites annually in the USA alone, solutions like these are welcomed by all organizations.

Furthermore, Folio3 offers an AI-powered Road and Safety solution that allows the analysis of the road and traffic situation through deep learning machine vision. It is a must-have solution for most road and safety situations as it not only allows for identification of the class of vehicle but also the rate of travel and the level of congestion.

Conclusion

Computer vision is by no means a fledgling concept. The idea has tickled the minds of innovators since the advent of the first robotic technologies. Nonetheless, computer vision in manufacturing still has significant room to grow, and the number of possible applications will only grow in time.

The idea that AI has the same ability to make decisions based on visual input without the need for manual data entry is spectacular. But since the AI will perform according to the training data provided, it is best to connect yourself with a certified machine learning service provider to avoid any unnecessary hiccups.

Start Gowing with Folio3 AI Today

Connect with us for more information at [email protected]